Fuel Polishing

What is Fuel Polishing?

Fuel polishing is a crucial technical cleaning process designed to eliminate microbial contamination from stored oil and hydrocarbon fuel. When fuel is left unused, it begins to break down, accumulating contaminants such as water, sediment, algae, and microbes. These impurities degrade fuel quality, leading to clogged filters, pumps, and injectors, causing unexpected shutdowns and critical failures.

Why Fuel Polishing Is Important?

A facility has a generator for a single purpose; to operate when it is called upon. Fuel in a standby generator can sit in the tank for months or even years before it is used. Over that length of time, the fuel is no longer the quality it was at purchase. Without fuel, a generator will not run. Without quality fuel a generator will eventually experience unexpected and costly breakdowns. It’s a fact that over 90% of all engine failures are due to poor fuel quality. Fuel polishing is essential for ensuring a reliable fuel supply and that a generator will start and run when called upon.

Removing those contaminants and bringing the fuel back to a condition it was originally intended proves to be a critical component of any maintenance program aimed at ensuring the stability of your fuel supply and safeguarding the optimal functioning of your equipment during crucial operational periods.

How Often Should I Polish My Fuel?

Fuel Replacement vs. Fuel Polishing

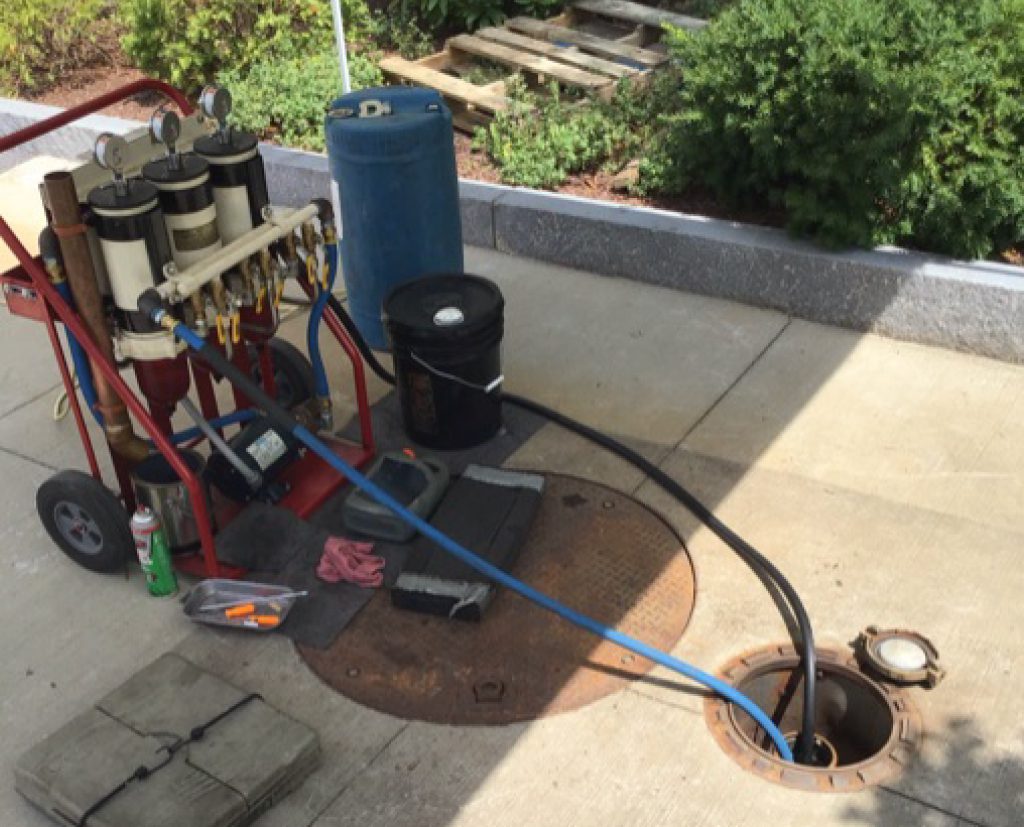

Fuel polishing emerges as a cost-effective alternative to the expensive option of fuel replacement, especially for facilities with bulk fuel storage. Some tanks hold over $100,000 worth of fuel, making it impractical to replace such large quantities. Instead, specialized equipment can revitalize stored fuel at a much lower cost, making it a fiscally responsible choice.

Facility managers view fuel as a critical asset that must be protected and maintained. Therefore, serious fuel maintenance procedures, including regular fuel polishing, are implemented to ensure the longevity and optimal performance of stored fuel.

Fuel Polishing Frequently Asked Questions

Weld Power Generator’s fuel polishing program ensures your generator runs with clean diesel fuel, reducing the risk of engine failure, minimizing sludge buildup, and contributing to a lower carbon footprint.

By implementing fuel polishing into your maintenance program, you can expect the following:

- Cleans and lubricates the injection system.

- Reduces smoke produced by the diesel power generator/fire pump.

- Mitigates sludge buildup issues, including sediment, rust, and water.

- Lowers the likelihood of fuel injector failure.

- Provides a more reliable fuel source for outages and emergencies.

- Helps in keeping maintenance expenses lower.

Yes, generator fuel quality testing is crucial. Weld Power Generator’s fuel analysis package adheres to NFPA 110 and ASTM D975 standards, ensuring your fuel meets the necessary criteria for optimal performance.

Our testing covers the following parameters:

- Appearance: Visual inspection indicating water entrainment or sediment.

- Microbe Count: Measuring bacterial and fungal colonies for contamination assessment.

- Centrifuge: Spinning the fuel sample to identify bottom sediment and/or water.

- Inorganic Components: Detecting metallic content in parts per million (ppm).

- Organic Contaminants: Identifying contaminants such as gasoline, solvents, and sludge.

- Accelerated Aging Stability Index: Predicting fuel stability over 6-12 months.

The patented stability test results are as follows:

- 3 or less: Fuel will likely remain stable with little to no further degradation.

- 4-10: Fuel is unstable, and further degradation is imminent.

- 11 and greater: Fuel is highly unstable, forming sediment rapidly, requiring immediate attention.