6 Critical Diesel Fuel Management Strategies to Prevent Gelling and Failure

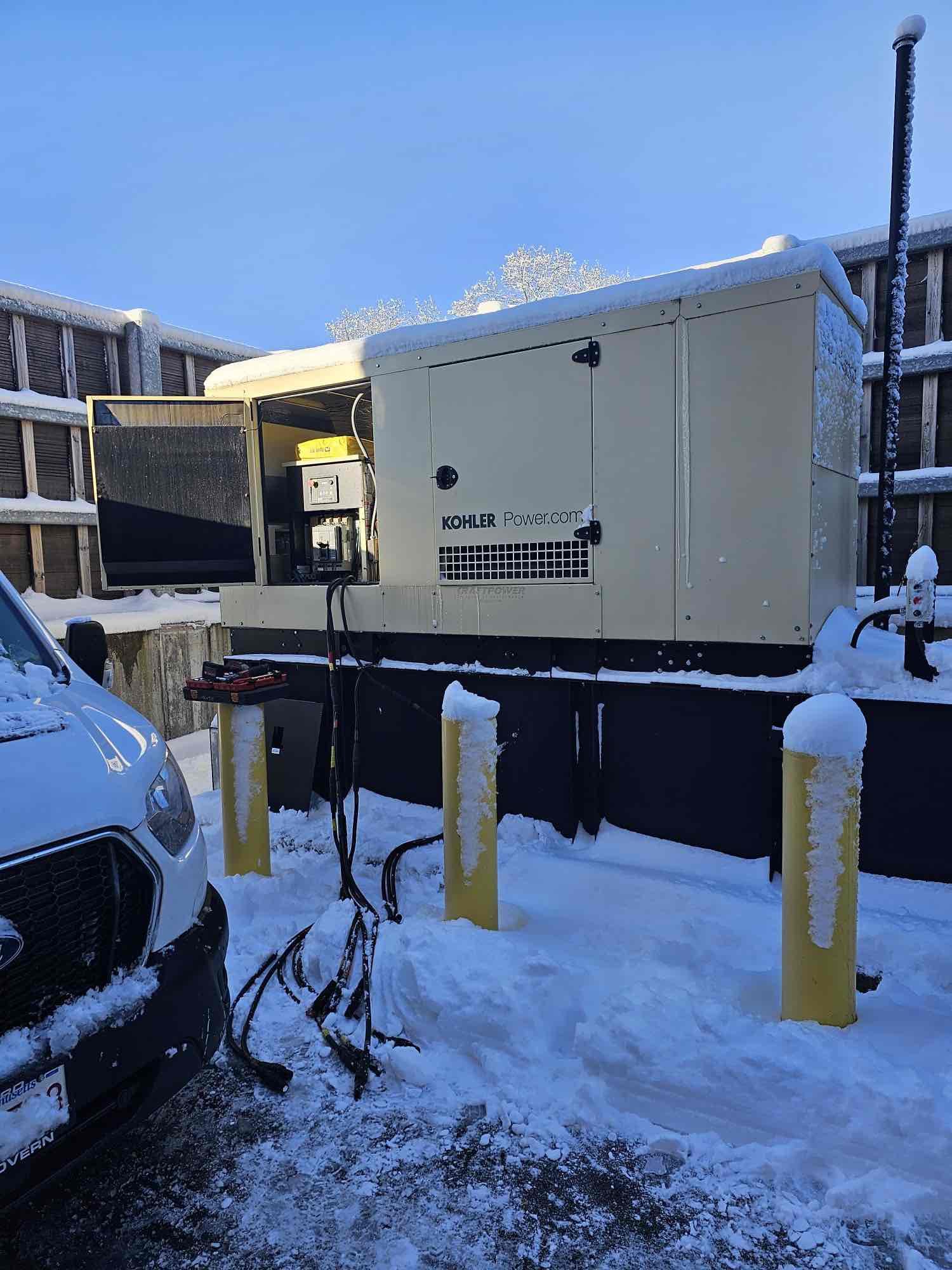

When discussing generator reliability, most conversations focus on engines, alternators, transfer switches, and maintenance schedules. However, one of the most overlooked, and most common, causes of generator failure is fuel quality and fuel management.

For many facilities, the diesel fuel stored in the tank of their standby generator is not something they think about. If it is not properly selected, maintained, and conditioned, it can become the point of failure during a power outage.

Table of Contents

Fuel Is Part of the System, Not Just What Powers It

A diesel generator is only as reliable as the fuel feeding it. Unlike engines that operate daily, standby generators may sit idle for months. During that time, fuel degradation can quietly occur inside the tank.

Contaminated, degraded, or improperly blended fuel can cause:

- Hard starting or no-start conditions

- Injector fouling

- Reduced power output

- Clogged fuel filters

- Excessive smoke

- Fuel pump damage

- Complete system shutdown

How Temperature Impacts Diesel Fuel Performance

Temperature plays a significant role in diesel fuel behavior, particularly in colder climates.

Understanding Fuel Gelling

Standard diesel fuel contains paraffin wax. In warm conditions, it remains dissolved and harmless. As temperatures drop, wax crystals begin to form.

There are three critical temperature thresholds:

- Cloud Point – Wax crystals begin forming, fuel appears cloudy.

- Cold Filter Plugging Point (CFPP) – Wax crystals clog filters.

- Pour Point – Fuel becomes too thick to flow.

If untreated fuel gels in a generator system:

- Fuel filters clog

- Fuel flow to injectors is restricted

- The engine may stall or fail to start

- Emergency power may be lost entirely

This is why winter preparation is not optional in colder regions.

Winter Blend Diesel Fuel: What is It?

In colder climates, suppliers offer winter blend diesel, typically a mix of:

- No. 2 Diesel (standard diesel)

- No. 1 Diesel (kerosene-based fuel with lower wax content)

Winter blend fuel:

- Lowers the cloud point

- Improves cold flow characteristics

- Reduces the risk of filter clogging

- Enhances cold weather starting

However, winter blend fuel has slightly lower energy content due to the No. 1 diesel component. This is generally a minor trade-off compared to the risk of fuel gelling.

For facilities storing large volumes of diesel, coordination with your fuel supplier before seasonal temperature drops is essential. Waiting until after a cold snap can be too late.

Diesel Fuel Protection

Even with winter blend fuel, additives play a critical role in protecting stored diesel.

Anti-Gel Additives

- Modify wax crystal formation

- Prevent large crystal structures from clogging filters

- Improve cold flow performance

These should be added before temperatures drop below the cloud point, not after fuel has already gelled.

Stabilizers for Long-Term Storage

Diesel fuel degrades over time due to:

- Oxidation

- Microbial growth

- Water contamination

- Sediment accumulation

Stabilizers help:

- Slow oxidation

- Preserve cetane levels

- Reduce sludge formation

- Extend usable storage life

For standby systems that may store fuel for 12–24 months, stabilizers are strongly recommended.

Biocides

Biocide treatments control microbial growth, particularly in systems with known moisture issues. Water intrusion in diesel tanks creates the perfect environment for microbial growth (often called “diesel algae,” though it is bacteria and fungi).

Microbial contamination can:

- Plug filters

- Create corrosive byproducts

- Damage fuel tanks and injectors

Fuel Quality Monitoring and Maintenance

Fuel management is not a one-time decision, it is an ongoing process that should include both routine fuel testing and fuel polishing.

Fuel Testing

Fuel sampling and analysis evaluates the condition of stored diesel by checking for water content, sediment, microbial presence, oxidation stability, and cetane levels. Periodic testing allows facility managers to identify developing issues early and take corrective action before generator performance is affected.

Fuel Polishing

Fuel polishing systems are designed to remove water and particulates from stored diesel fuel. These systems continuously circulate and filter the fuel within the tank, helping to eliminate contaminants and restore the fuel to a usable condition. For facilities that store large volumes of diesel or maintain long-term reserves, fuel polishing is an important component of reliability planning.

Tank Inspections

Regular tank inspections are equally critical to maintaining fuel integrity. Inspections help identify condensation buildup, internal corrosion, fuel leaks, and venting issues that may contribute to contamination or degradation over time.

For mission-critical facilities, annual or bi-annual fuel inspections and testing are considered best practice to ensure dependable generator performance when it is needed most. is often standard practice.

The Cost of Ignoring Fuel Management

If utility power is lost and the generator shuts down due to degraded or contaminated fuel, the consequences can be severe. Facilities may experience immediate production downtime, spoilage of food or pharmaceuticals, and disruption of other temperature-sensitive operations. In healthcare and other life-safety environments, generator failure during an outage can compromise critical systems and, in worst-case scenarios, place lives at risk.

When compared to these risks, proactive fuel treatment, seasonal fuel preparation, and routine testing represent relatively minimal investments that protect both equipment and operational continuity.

Best Practices for Diesel Generator Fuel Reliability

To ensure dependable performance:

- Confirm seasonal fuel type with your supplier.

- Treat stored fuel with appropriate additives before temperature changes.

- Implement a routine fuel testing schedule.

- Address water intrusion immediately.

- Consider fuel polishing for large or long-term storage tanks.

- Exercise generators regularly to circulate fuel through the system.

Final Thoughts: Fuel Is Preventative Maintenance

A diesel generator can be meticulously maintained — oil changed, batteries replaced, load bank tested — yet still fail because of compromised fuel.

Fuel should be viewed as an integrated component of the power system, not simply what fills the tank.

For facilities that depend on uninterrupted power, proper fuel selection, seasonal preparation, and ongoing fuel maintenance are not optional. They are essential elements of a comprehensive reliability strategy.