What 75 Years of Preventative Maintenance Teaches You About Reliability

After 75 years in the power generation industry, one lesson stands out above all others: generator reliability is built long before an outage ever occurs. Preventative maintenance has always been the foundation of dependable standby power, but how it is approached, and how critical it has become, has evolved significantly over time.

Decades of servicing generators across a wide range of industries have reinforced several core truths about what preventative maintenance really accomplishes and why it remains essential today.

Table of Contents

Preventative Maintenance Is About Risk Reduction, Not Just Runtime

Early generator maintenance was often reactive. Equipment was serviced based on hours run or after a failure occurred. Over time, it became clear that the true purpose of preventative maintenance is not simply keeping an engine running, it is reducing operational risk.

Preventative maintenance addresses:

- Hidden mechanical and electrical issues

- Environmental and site-specific conditions

- Fuel degradation during long standby periods

- Wear that may not trigger alarms until failure occurs

Seventy-five years of field experience shows that most generator failures are preventable when systems are inspected, tested, and serviced consistently.

Consistency Matters More Than Complexity

As generator systems became more advanced, maintenance programs also grew more detailed. However, experience has shown that consistency is more important than complexity.

Effective preventative maintenance programs share common characteristics:

- Clearly defined service intervals

- Standardized inspection procedures

- Documented findings and corrective actions

- Follow-through on recommended repairs

Missed inspections, deferred service, or incomplete maintenance introduce uncertainty, often at the worst possible time. Reliable systems are the result of disciplined execution, not occasional attention.

Fuel Quality Is One of the Most Overlooked Risks

Over decades of generator service, fuel-related issues have proven to be one of the most common causes of failure. Diesel fuel can degrade over time, particularly in standby applications where fuel sits unused for extended periods.

Preventative maintenance programs that prioritize fuel management help mitigate risks such as:

- Water contamination

- Microbial growth

- Fuel stratification and sediment buildup

Routine fuel testing and polishing, when necessary, ensure that generators will perform as expected when called upon.

Load Testing Reveals What Visual Inspections Cannot

Visual inspections and no-load exercise runs are valuable, but they do not fully validate system performance. One of the most important lessons learned over 75 years is that load testing is essential to confirming reliability.

Building Load Testing and Load Bank Testing help:

- Verify the generator’s ability to carry rated load

- Identify cooling, exhaust, or fuel delivery issues

- Prevent wet stacking in diesel engines

- Confirm proper operation of transfer switches and controls

A generator that starts is not necessarily a generator that will support a facility under real operating conditions.

Batteries and Electrical Components Deserve Equal Attention

Many generator failures are traced back to batteries or electrical components rather than the engine itself. Preventative maintenance programs that focus exclusively on mechanical systems often overlook these critical elements.

Best practices include:

- Regular battery testing and replacement

- Inspection of chargers, wiring, and terminations

- Verification of alarm and shutdown circuits

Seventy-five years of service experience confirms that small electrical issues can have outsized consequences during an outage.

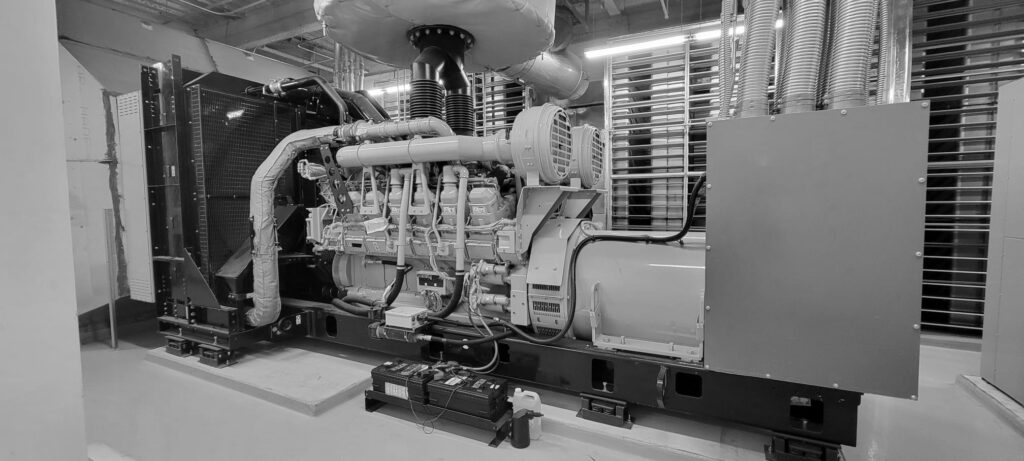

Maintenance Is a System-Level Responsibility

Modern standby power systems are no longer standalone generators. They include transfer switches, paralleling gear, fuel systems, controls, and monitoring platforms. Preventative maintenance must address the entire system, not individual components in isolation.

A system-level approach ensures:

- Seamless load transfer

- Coordinated operation across multiple assets

- Compliance with codes and standards

- Faster diagnosis when issues arise

Reliability depends on how well all components work together.

Documentation Turns Maintenance Into Accountability

One of the most important changes in preventative maintenance over the decades is the role of documentation. Detailed service records transform maintenance from a task into a management tool.

Accurate documentation supports:

- Regulatory and insurance compliance

- Budget planning and asset lifecycle decisions

- Trend analysis and predictive maintenance

- Clear communication between service providers and facility managers

What gets documented gets managed.

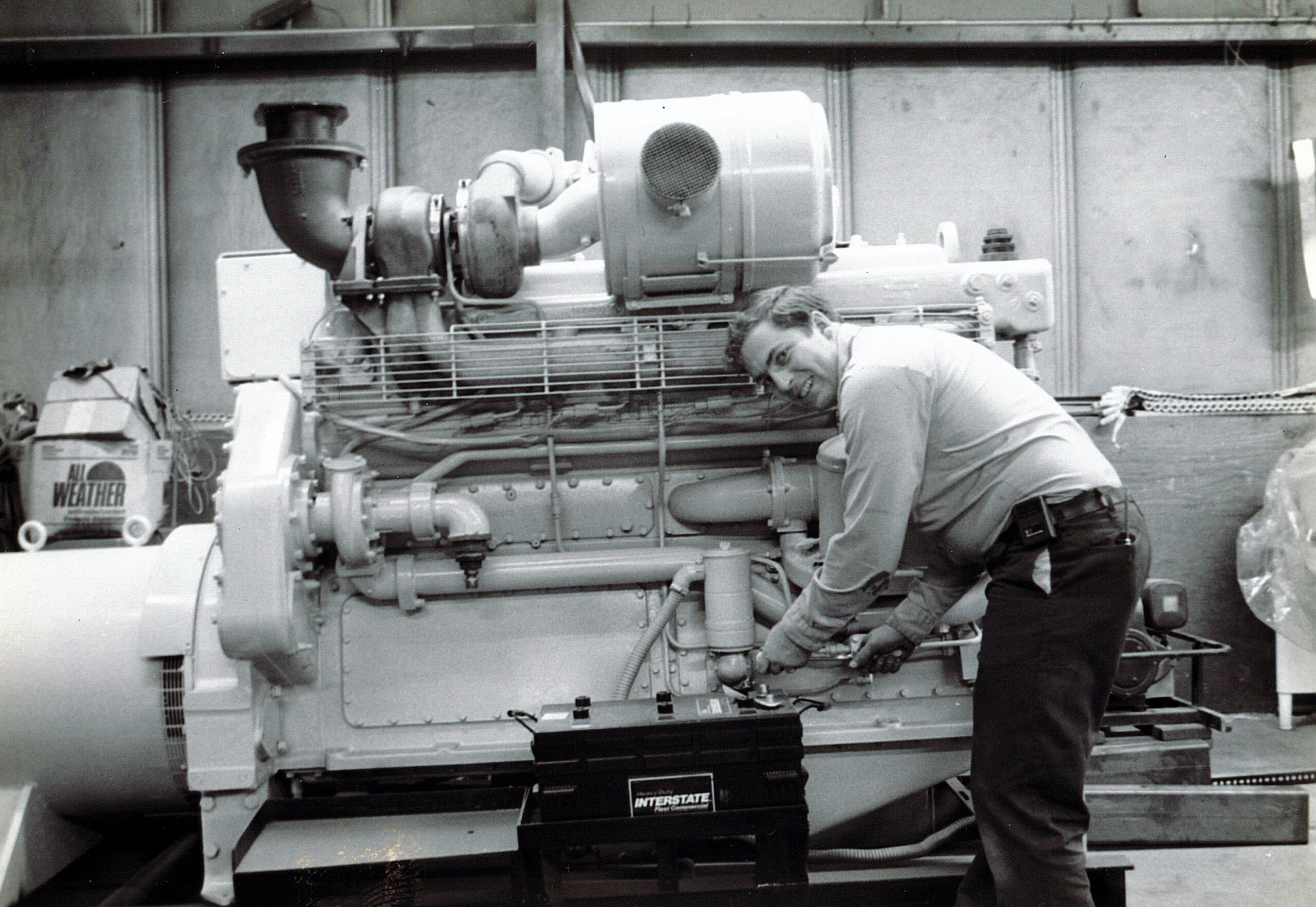

The Long View: Experience Still Matters

Technology has improved, tools have become more sophisticated, and monitoring is now data-driven. However, after 75 years, one truth remains unchanged: experience matters.

Preventative maintenance is most effective when it is guided by professionals who understand failure patterns, environmental impacts, and real-world operating conditions, not just manufacturer checklists.

As Weld Power marks 75 years in business, preventative maintenance remains at the core of what keeps critical power systems reliable. The lessons learned over decades continue to shape how systems are maintained today, and how they will be protected in the future.