What is Fuel Polishing? 4 Things You Need to Know.

If you’ve got large diesel fuel storage at your worksite you’re likely in for a rude surprise once you attempt to utilize your reserves.

If stored fuels aren’t routinely treated and tested, they will become contaminated over time and will need fuel polishing. So, what is fuel polishing? You’ll learn everything you need to know about fuel polishing in this article.

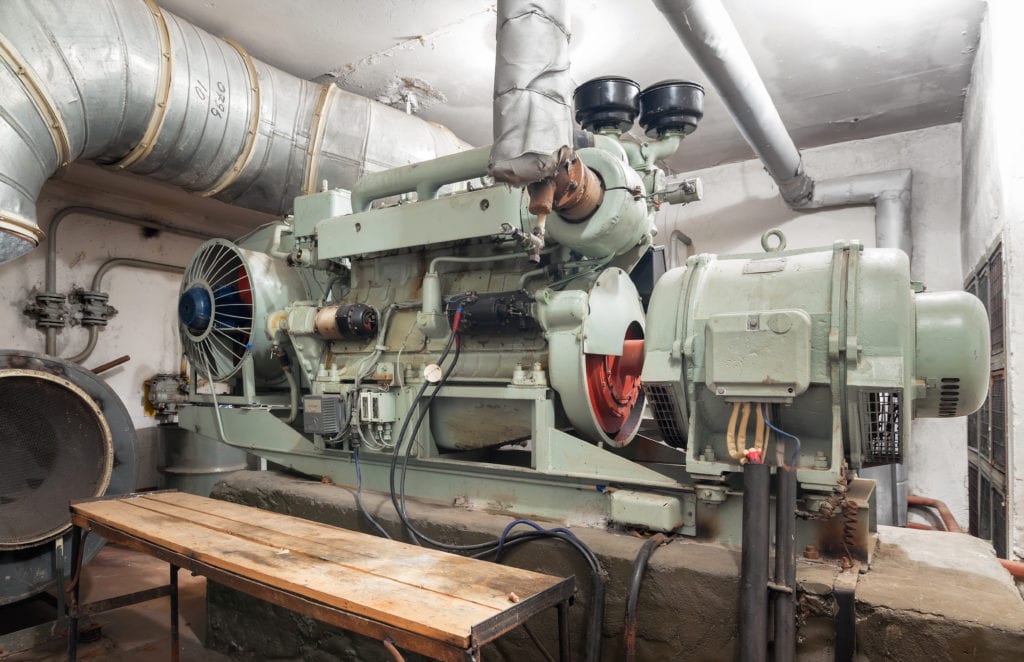

It’s bad news for any machine you depend on with these fuels, as the built-up contaminants could end up gumming up your engine to the point of failure. This is especially problematic for the back-up power industry which relies heavily on their accompanied fuel tanks during an emergency.

The contamination of the fuel is a major cause of premature shutdowns for standby generator sets, fire pump engines, and other diesel engine support functions. As the length of the storage period increases, the probability for premature engine shutdown due to either clogged filters, or excessive water entrainment increases. But don’t lose hope and dispose of your diesel fuel if it’s filled with sludge or has blackened to a worrying degree.

That’s where quality diesel fuel polishing service comes in to save the day! A thorough and consistent maintenance plan for your fuel tank should be incorporated into your back-up power maintenance service plan.

Table of Contents

What is fuel polishing?

Fuel polishing is the mechanical process of filtering stored fuels through an apparatus or multiple apparatuses that target and extract contaminants without the need (or with a significantly reduced need) for expensive and oftentimes inefficient fuel additives. So, what is fuel polishing exactly? For starters, diesel fuel polishing and other fuel polishing systems are lifesavers that can potentially save you thousands of dollars on fuel replacement or treatment. A good fuel polishing treatment will get your fuel reserves working like new, or as close to new as possible.

Diesel fuel polishing systems aren’t just a single-pass kind of deal, though. For diesel fuel polishing to effectively clean stored fuels and restore them to their former efficacy, multiple filtration apparatuses are required to target the various complex contaminants that build up in biodiesel, diesel, red diesel, and other fuels over time.

The best diesel fuel polishing systems either utilize separate machines with different filters, or an intricate collection of various filter technologies within one fuel polisher. Fuel polishing systems, at their most efficacious and safe, target the densest matter first — especially the matter built up near the suction side of the internal pumping side. This is because highly-pressurized contamination is a massive hazard and such pressurization primarily occurs on the suction side of a diesel fuel tank. Thus, the majority of the fuel polishing process should take place on the suction side for best (and safest) results.

What are the main contaminants that diesel fuel polishing targets?

There are three main types of contaminants which can plague your stored fuels when they’re left unattended and untreated for extended periods of time — solid particles, water, and microbial growth otherwise known as “diesel bugs.” Let’s take a closer look at these three categories of contaminants and how diesel fuel polishing can help rid them from your fuel reserves for good.

Solid Particles

- Dirt and grime

- Wax

- Soot

- Rust

- Simple & complex organic compounds

- Gums

The beginning stages of the diesel fuel polishing process usually targets solid matter first, excising the densest contaminants first. When you look at your fuel reserves and spot massive discoloration and dullness, it’s likely that what you’re actually seeing are a host of dense contaminants such as normal dirt, rust, and wax. The fuel polishing process will excise these solid particles from your fuel supply, thus bringing you fuel closer to its original color and usefulness.

Water

- Free water

- Emulsified water

- Dissolved water

While water is essential for human life, it can spell absolute disaster for engines. Yes, diesel fuels and other fuel sources do have a tiny amount of water within them. However, excess water buildup decreases the efficacy of fuel sources, endangers engines built to process fuel and fuel alone, and also serves as a breeding ground for dangerous and harmful microbes.

Water contamination starts in dissolved form, barely noticeable at first or second glance. Then the mixture of water and oil will emulsify, clouding the fuel and greatly decreasing its overall utility. Finally, free water gathers in puddles in the oil and becomes a playground for all kinds of bacterial badness. Diesel fuel polishing excises these different forms of water at all stages of the process to ensure that your fuel is safe for use.

Diesel Bugs (Microbial Growth)

- Mold

- Yeast

- Bio-films

- Bacteria

Not so affectionately referred to as diesel bugs, microbial contaminants in diesel fuel are a prime suspect when faced with blocked and gummed fuel filters, worn-out fuel injectors, corrosion in fuel tanks, and abject engine and fuel system failure. They’re also the trickiest contaminants for diesel fuel polishing systems to target and excise.

For starters, a normal fuel polishing treatment will only break up and filter out the sludgy biomass formations that diesel bugs create. It won’t actually kill or remove the microbes in the fuel tank itself. For this to happen, a diesel fuel polishing treatment must be used in conjunction with a biocide treatment in the early stages of the process. Biocide treatments will kill and excise the bacterial, yeast, and other microbial matter at the source for maximum and lasting effectiveness.

What are some problems which can pop up during the diesel fuel polishing process?

For starters, questionable diesel fuel polishing systems that sacrifice stability for a speedy decontamination process can do more harm than good. Diesel fuel cleaning machines polish fuels at rates that vary from 8 liters to a staggering 400 liters per minute. While faster flow rates may seem great in theory, fuel polishing systems that go too fast can damage your fuel tanks and dangerously increase pressurization.

A lackadaisical approach by a diesel fuel polishing technician can also spell huge problems for your fuel efficacy and the equipment you fill with said fuel. While good fuel polishing systems have multiple water separation filters to excise water from your fuel tanks, the technician should also take care to manually suction out the tank’s water bottoms as thoroughly as possible. If they don’t, there’s a chance the filters will miss something. After all, even the best of fuel processing equipment is fallible at times.

And to be honest, all diesel fuel polishing systems aren’t created equal. If you settle for a budget fuel polishing service that attacks the visible symptoms of fuel contamination without using the right chemical treatments to address the cause, you’ll have spent money on a surface-level diesel fuel polishing treatment that’s basically the equivalent of a band-aid on a mortal wound.

What are the key things to look for in a quality fuel polishing service?

As we stated before, haphazard diesel fuel processing services which prize speed over substance are a danger to your fuel and your equipment. Look for a fuel polishing service with a great track record of success, be it online reviews or word of mouth. Question them about their process, the chemicals they use, and what exactly they’re going to be doing to approach and attack your fuel contamination problem.

A quality diesel fuel processing service will conduct a thorough fuel analysis before the process gets underway. This way, the exact contamination problem can be pinpointed and the right equipment and chemicals can be used right away to get the job done.

Also, a good fuel polishing service will have more than fuel filtration systems at their disposal. Whether it’s biocide to eliminate nasty diesel bugs right at the source or the proper chemical stabilizer to ensure that asphaltene and sludge formations are excised for good without a chance of reformation, your diesel fuel polisher needs to have a lot more than some fancy equipment in tow to make your fuel polishing experience worthwhile.

In short, quality fuel polishing services are prepared for everything and anything that your fuel tanks throw at them. Look for experienced diesel fuel processing technicians who have been around the block a time or two. They’re the ones that will take more time to get the fuel processing job done right, rather than blowing through the diesel fuel polishing process as quickly as possible.

After all, what is fuel polishing if it doesn’t actually save your fuel and protect both your fuel tanks and the engines of your prized equipment?

Closing thoughts

If your business relies on back-up emergency generator power then you need to maintain the fuel in that tank. The right diesel fuel polishing service will prolong the life of your stored diesel fuel and help protect the equipment associated with the fuel tank. Your emergency power source is your diesel fuel. Take care of it.