University Generator Management: A Facilities Director’s Guide to Emergency Power on Campus

A university campus is unlike any other facility. In a single square mile, you might have residence halls full of sleeping students, a research laboratory running temperature-sensitive experiments, a hospital or medical center, a data center processing thousands of records, an arena hosting a sold-out event, and a dining hall preparing breakfast for thousands of people, all at the same time, all depending on reliable power.

When the power goes out, the stakes on a university campus are exceptionally high. Emergency power isn’t a convenience, it’s a legal requirement, a life-safety necessity, and a core operational responsibility. Yet many higher education institutions are operating with aging generator infrastructure, inconsistent maintenance programs, and emergency response plans that haven’t been tested under real conditions.

At Weld Power Generator, we’ve spent over 75 years supporting mission-critical facilities across the Northeast, including colleges and universities that can’t afford to get emergency power wrong. This guide is designed to help facilities directors and operations managers understand the full scope of university generator management: what’s required, what’s commonly overlooked, and how to build a program that protects your campus no matter what.

Table of Contents

Why University Campuses Have Unique Emergency Power Challenges

Most commercial facilities have one or two critical loads to protect in a power outage. Universities have dozens, and each one has different requirements, different regulatory frameworks, and different tolerances for downtime.

Diverse Building Types Across a Single Campus

A typical university campus might include:

- Residence halls and dormitories, where student safety depends on lighting, HVAC, and communication systems

- Research laboratories with cryogenic storage, ongoing experiments, and sensitive equipment that cannot tolerate even a momentary power interruption

- Campus data centers and server rooms managing student records, financial systems, and institutional communications

- Medical and counseling centers, often subject to the same NFPA 110 requirements as hospitals

- Dining facilities and commercial kitchens that need power to safely store and prepare food

- Athletic facilities and arenas that may be hosting events with thousands of spectators

- Administrative buildings, libraries, and classrooms where business continuity matters

- Utility plants, boiler rooms, and mechanical systems that serve the entire campus

Each of these building types may require a separate generator, a separate service and maintenance schedule, and a separate compliance framework. Managing all of them as a cohesive system, rather than a collection of independent generators, is one of the defining challenges of university facilities management.

Regulatory Requirements: What Universities Must Know

Generator compliance for universities is governed by a layered set of codes and standards. While requirements vary by state and by the specific nature of the facility, the following frameworks are the most commonly applicable.

NFPA 110: Standard for Emergency and Standby Power Systems

NFPA 110 is the foundational standard for emergency power systems in the United States. It governs how generators must be installed, tested, maintained, and documented. For university facilities, NFPA 110 applies to any building where emergency power is required, including buildings with elevators, buildings over a certain occupancy threshold, and any facility providing healthcare services.

Key NFPA 110 requirements include:

- Monthly exercise testing of generators under load for a minimum of 30 minutes

- Annual load bank testing if monthly testing cannot be performed at or above 30% of the generator’s nameplate rating

- Detailed maintenance logs and inspection records that must be retained and available for inspection

- Transfer time requirements — most Level 1 systems must transfer to emergency power within 10 seconds

NFPA 101: Life Safety Code

NFPA 101 addresses life safety requirements in occupied buildings, including dormitories, assembly spaces, and educational facilities. It specifies minimum emergency lighting requirements and exit sign illumination that must be maintained during a power failure, most of which are backed by generator systems.

The Joint Commission (for Campus Medical Facilities)

Universities with on-campus health centers, hospitals, or clinical facilities that are accredited by The Joint Commission are subject to its Environment of Care standards, which include rigorous generator testing and documentation requirements. These facilities are essentially held to hospital-level standards for emergency power reliability.

State-Level Requirements

In Massachusetts, Connecticut, Rhode Island, New York, and other Northeast states, there may be additional state-level inspection and reporting requirements layered on top of the national standards. In Massachusetts, for example, the Board of Building Regulations and Standards (BBRS) enforces the state building code, which incorporates NFPA standards by reference. Facilities managers should work with a generator service provider who understands the specific requirements in their state.

The Critical Importance of Research Laboratory Power

Of all the facilities on a university campus, research laboratories often carry the highest risk in a power outage, and the most significant financial exposure.

A single power interruption in a research lab can mean:

- Loss of cell cultures, tissue samples, or biological specimens that took months to develop

- Compromise of controlled-environment experiments with no possibility of restarting

- Failure of cryogenic freezers storing irreplaceable samples at ultra-low temperatures

- Loss of expensive reagents and compounds that require refrigeration

- Research data loss if servers or instruments lose power during active recording

- In extreme cases, chemical or biological safety hazards if containment systems lose power

For research labs with active NIH, NSF, or DOD grants, a power-related loss of samples or data can jeopardize not only current grant funding but future funding eligibility. The financial stakes easily run into the hundreds of thousands of dollars.

Research laboratory emergency power systems often require a higher standard than standard NFPA 110 compliance. Best practice includes generator systems with no-break or very fast transfer times, uninterruptible power supply (UPS) integration, and real-time remote monitoring so that any anomaly is flagged and addressed before a failure occurs.

Dormitories and Student Life: The Human Element

When the lights go out in a residence hall, you’re not just dealing with an operational inconvenience, you’re responsible for the safety and wellbeing of hundreds or thousands of students. Emergency lighting, stairwell illumination, electronic door access systems, fire alarm panels, and communication systems must all remain operational during a power outage.

Universities with modern access control systems (card readers, electronic strikes, intercoms) need to ensure these systems are connected to a properly sized emergency power source. A poorly designed or undersized generator system can leave students locked out of buildings or, conversely, leave secured areas unsecured during a power event.

There’s also the issue of HVAC. In northern climates like New England, a winter power outage in an unheated dormitory presents a real safety risk within hours. Generators supporting residential buildings should be sized to handle not just life-safety loads but essential HVAC operation as well, particularly in facilities housing students with medical needs.

Preventive Maintenance: The Foundation of Campus Generator Reliability

The most common reason university generators fail during an actual power outage isn’t mechanical age, it’s inadequate maintenance. Generators that sit idle for months between tests, that run low on coolant or oil, or that have degraded fuel from long-term storage are at significant risk of failure precisely when they’re needed most.

A comprehensive preventive maintenance program for a university campus should include:

Monthly Exercise Testing

As required by NFPA 110, each generator should be run under load for at least 30 minutes each month. Monthly tests are an opportunity to observe the generator under operating conditions, check for exhaust issues, verify transfer switch operation, and document performance. These tests should be scheduled at consistent intervals and performed by qualified technicians.

Annual Load Bank Testing

Load bank testing is the gold standard for verifying generator performance. A load bank test uses a controlled resistive load to exercise the generator at its rated capacity for an extended period, typically two to four hours. This process reveals hidden issues that a standard monthly test under light load may not expose, including wet stacking (carbon and oil buildup in diesel exhausts from running under light load), cooling system capacity, and fuel consumption rates.

For universities with generators that primarily run at low load during monthly tests, annual load bank testing is not just recommended, it’s required.

ATS (Automatic Transfer Switch) Maintenance

The automatic transfer switch is the device that detects a utility power failure and automatically switches your building’s load to generator power. It’s arguably the most critical component in the emergency power system, and it’s frequently overlooked in maintenance programs. A generator that starts perfectly and runs beautifully is useless if the transfer switch fails to operate.

ATS maintenance should include inspection of contact surfaces, exercising of transfer mechanism, testing of voltage and frequency sensing, and documentation of transfer timing. Many facilities directors don’t realize their ATS devices have their own manufacturer-recommended maintenance intervals, separate from the generator itself.

Diesel Fuel Polishing and Management

University generators often sit with full fuel tanks for months or years between significant use. Diesel fuel degrades over time — it oxidizes, develops microbial contamination, and generates sludge that can clog fuel filters and injectors. Fuel polishing is the process of filtering and reconditioning stored diesel fuel to restore it to a usable condition.

Best practice is to fuel sample annually and polish or replace fuel as needed. Stored diesel that is more than 18-24 months old without treatment is a liability, and it’s one of the most common causes of generator failure during extended outages.

Remote Monitoring

For a campus with dozens of generators spread across many buildings, remote monitoring is a game-changer. Modern monitoring systems connect to each generator’s control panel via cellular or hardwired connection and provide real-time data on operating status, battery health, fuel level, active alarms, and run hours.

Weld Power Generator’s remote monitoring platform gives both our technicians and your facilities team 24/7 visibility into your entire generator fleet. When an anomaly is detected (a low battery, a failed start attempt, a transfer switch that didn’t complete) we can respond before a small problem becomes a major failure.

Emergency Generator Rentals: Planned Events and Unplanned Outages

Beyond permanent standby systems, universities have a significant need for temporary generator power, both planned and unplanned.

Planned Events

Graduation ceremonies, outdoor concerts, athletic events, and large outdoor gatherings often require temporary power that exceeds what permanent infrastructure can support. Renting a generator or multiple generators in parallel allows event coordinators to meet peak demand without permanent infrastructure investment.

Construction and Renovation

Campus construction and renovation projects frequently require temporary power when utility connections are interrupted. A properly sized rental generator keeps critical building systems running during construction without disrupting building occupants.

Emergency Response

When a utility outage is extended (due to a storm, grid failure, or equipment damage) rental generators can supplement or replace permanent systems that may not have been sized to run indefinitely. Weld Power maintains one of the largest rental generator fleets in the Northeast, with units ranging from 20kW to 2,000kW, and we can mobilize quickly in response to an emergency.

Building a Campus-Wide Generator Management Program

For universities managing ten, twenty, or even fifty generators across a large campus, a piecemeal approach to maintenance doesn’t work. What’s needed is a structured, campus-wide program that brings consistency, accountability, and documentation to every generator in your portfolio.

Here’s what a best-in-class university generator management program looks like:

- A complete, up-to-date asset inventory of every generator and transfer switch on campus, including make, model, age, kilowatt rating, fuel capacity, and last service date

- Consistent, documented preventive maintenance at intervals defined by NFPA 110 and manufacturer recommendations

- A single point of contact for all service to ensure consistency and accountability

- Annual load bank testing for all generators, not just those flagged as underperforming

- ATS testing and maintenance included in the program, not treated as an afterthought

- Fuel management protocols including regular sampling and treatment

- Real-time remote monitoring for all generators, with alert escalation to both the service provider and campus facilities staff

- An emergency response plan that defines who to call, what steps to take, and what rental assets are available when an outage occurs

- Compliance documentation maintained and organized for regulatory inspections on short notice

Working with a single experienced generator service provider across your entire campus, rather than relying on separate contractors for different buildings, is one of the most effective ways to build consistency and reduce both cost and risk.

Why Choose an Independent Generator Service Provider Over an OEM?

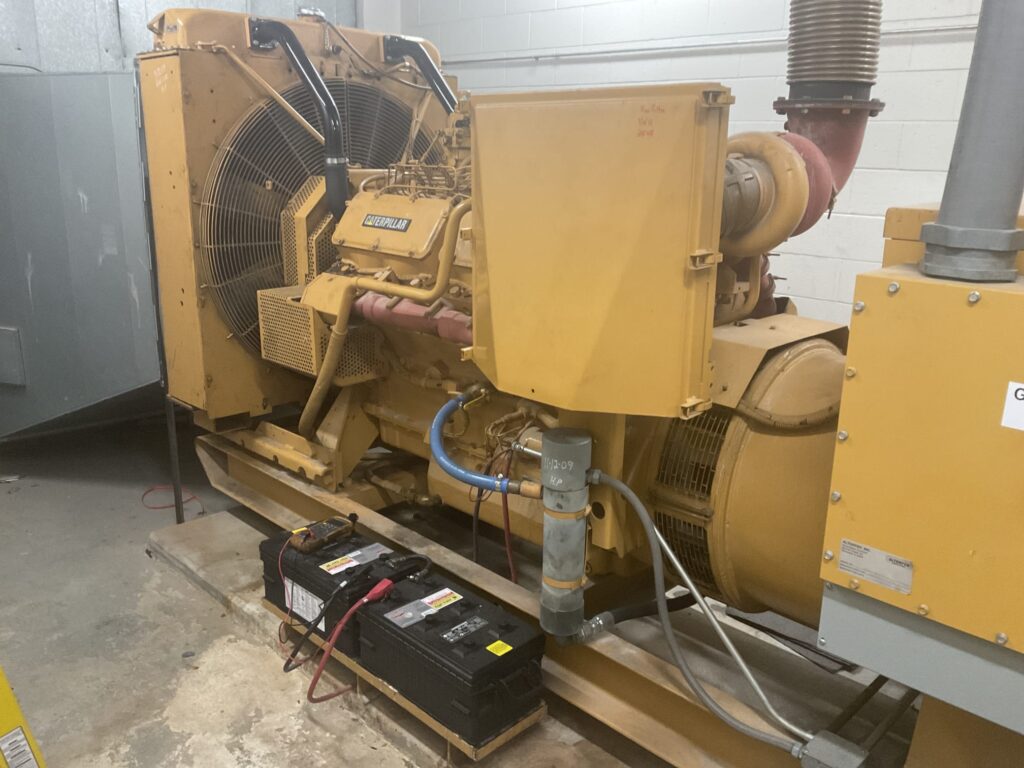

Many universities find themselves locked into service contracts with the original equipment manufacturer (Caterpillar, Kohler, Generac, Cummins, or others). While OEM service has its place, there are compelling reasons why an independent, multi-brand specialist like Weld Power Generator often delivers better value for a university campus.

University campuses rarely have a single-brand generator fleet. Over the decades, buildings get built, generators get purchased from different vendors, and you end up with a mix of makes and models. An OEM provider specializes in their own brand, meaning you may need multiple contracts and multiple points of contact to cover your entire campus.

Weld Power Generator’s technicians are trained and EGSA (Electrical Generating Systems Association) certified, so we can service all makes and models of generators and transfer switchgear. This means one service relationship, one invoice, one point of accountability for every generator on your campus, at a cost that’s typically 20-25% lower than manufacturer service contracts.

Ready to Build a Stronger Emergency Power Program for Your Campus?

Weld Power Generator has been supporting mission-critical facilities across Massachusetts, Connecticut, Rhode Island, New York, New Jersey, Pennsylvania and the broader Northeast since 1951. We understand the complexity of university campuses, the regulatory landscape, and the consequences of getting emergency power wrong.

Whether you need a comprehensive campus-wide maintenance program, help evaluating your current generator infrastructure, emergency rental equipment, or simply a second opinion from an EGSA-certified technician, we’re here to help.

Contact Weld Power Generator today to speak with one of our specialists and learn how we can support your campus’s emergency power needs.