How Generator Reliability Has Changed Over 75 Years

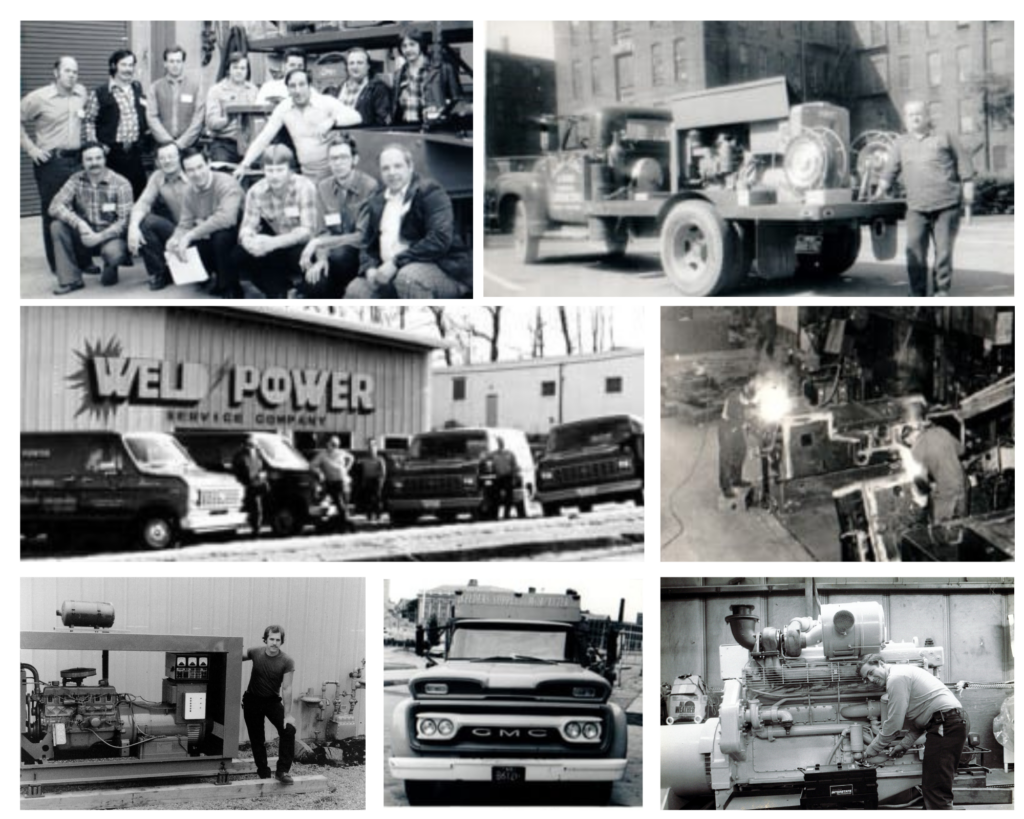

For 75 years, Weld Power Generator has worked alongside customers whose operations depend on reliable power. During that time, generator technology and the expectations placed on it have changed dramatically. What once served as basic backup equipment has evolved into highly engineered, data-driven systems designed to support mission-critical facilities with minimal tolerance for failure.

Understanding how generator reliability has changed over the decades helps explain why experience, proper maintenance, and system design matter more than ever.

Table of Contents

The Early Years: Mechanical Simplicity and Manual Oversight

In the early days of standby power, generator systems were largely mechanical. Engines were simple by today’s standards, control systems were minimal, and reliability depended heavily on operator knowledge and routine manual inspection.

Key characteristics of early generator reliability included:

- Limited automation and basic controls

- Manual start and transfer processes

- Minimal diagnostics or fault detection

- Heavy reliance on operator response

While these systems were often rugged, failures could go unnoticed until the generator was called upon during an outage. Preventative maintenance was important, but consistency varied widely from site to site.

The Rise of Automation and Transfer Switches

As facilities grew more complex and downtime became more costly, generator systems evolved to include automatic transfer switches (ATS) and improved control panels. These advancements significantly improved reliability by reducing human intervention during power outages.

Major improvements during this period included:

- Automatic detection of utility power loss

- Faster and more consistent generator start-up

- Improved voltage and frequency regulation

- Standardized maintenance procedures

Reliability was no longer just about whether the generator would run, it was about how quickly and smoothly it could assume the load.

Modern Engines, Controls, and Redundancy

Over the last several decades, generator reliability has been transformed by advancements in engine technology, digital controls, and system design.

Today’s generators benefit from:

- Sophisticated electronic control modules

- Integrated sensors monitoring temperature, pressure, and performance

- Redundant components for critical applications

- Improved fuel efficiency and reduced emissions

These systems are designed not only to respond to outages but to operate predictably under a wide range of conditions. However, increased complexity also means that reliability now depends on proper commissioning, programming, and ongoing service by trained professionals.

The Impact of Preventative Maintenance

One of the most significant shifts in generator reliability over 75 years is the role of structured preventative maintenance programs. Modern generators are engineered for longevity, but only when maintained according to manufacturer specifications and real-world operating conditions.

Effective maintenance today includes:

- Routine inspections and load testing

- Fluid analysis (oil, coolant, and fuel)

- Battery testing and replacement

- Fuel quality management and polishing

- Documentation and compliance tracking

Reliability is no longer reactive, it is planned, measured, and verified.

Remote Monitoring and Data-Driven Reliability

One of the most recent advancements in generator reliability is remote monitoring. These systems provide real-time insight into generator status, alarms, and performance metrics.

Remote monitoring improves reliability by:

- Identifying issues before they cause failures

- Reducing response times during alarms

- Supporting trend analysis and predictive maintenance

- Enhancing visibility for facility managers

Instead of waiting for a problem to occur, reliability is now actively managed through data and analytics.

Reliability Today: A System-Level Approach

After 75 years, one lesson is clear: generator reliability is no longer defined by the generator alone. It depends on the entire power system, including:

- Proper sizing and system design

- Transfer switches and paralleling gear

- Fuel systems and environmental conditions

- Maintenance planning and service response

Modern reliability is the result of experience, engineering, and disciplined execution.

Looking Ahead

As Weld Power celebrates 75 years in business, generator reliability continues to evolve. Emerging technologies, stricter regulations, and increasing demand for uptime will continue to shape how power systems are designed and maintained.

What remains unchanged is the importance of working with experienced professionals who understand both where the industry has been and where it is going.

For 75 years, Weld Power has helped customers navigate those changes, delivering reliable power solutions built for today and prepared for tomorrow.