8 Essential Generator Maintenance Tips You Can’t Ignore

Standby generators are essential for maintaining operations during unexpected power outages. Whether you’re powering a hospital, data center, commercial building, or critical infrastructure, your generator must be ready to perform flawlessly when called upon. But without proper maintenance, even the most robust generator systems can fail at the worst possible time. Here are 8 essential generator maintenance tips you simply can’t afford to ignore.

Table of Contents

Perform Routine Inspections

Regular visual inspections help identify early signs of wear, leaks, corrosion, or loose components before they become critical issues. Inspect the fuel system, battery, belts, hoses, and exhaust system. Look for anything unusual like puddles of fuel or coolant, frayed wires, or excessive soot.

Generator Maintenance Tip: Establish a monthly inspection routine, or more frequently if your generator operates in harsh environments.

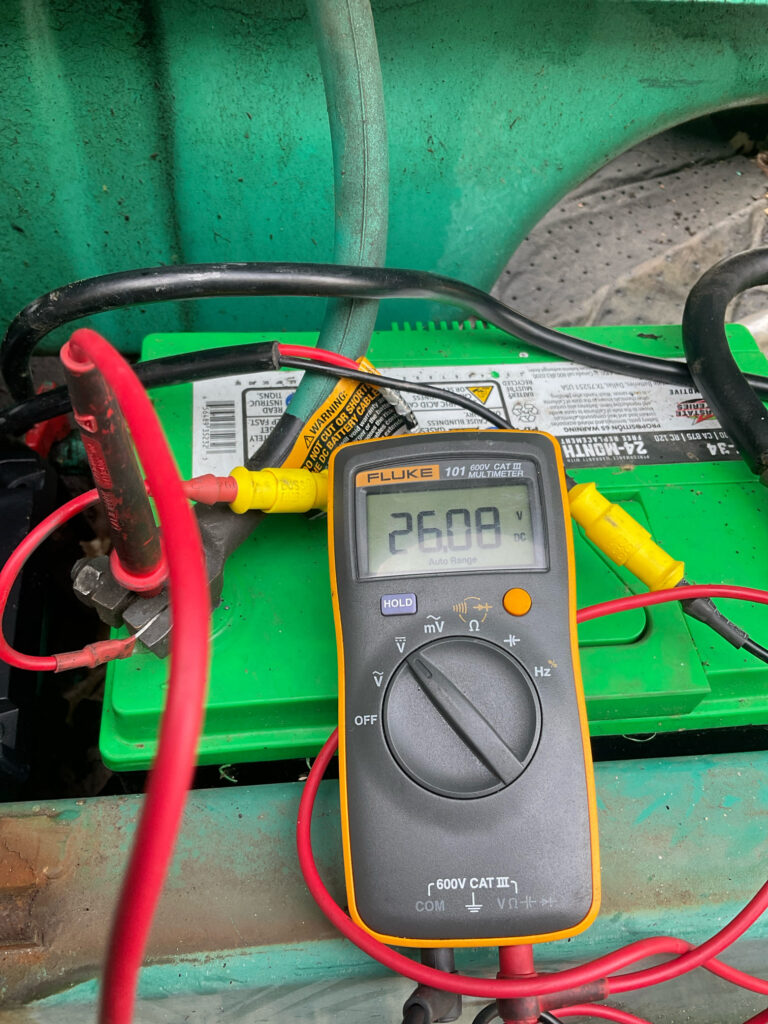

Test the Battery System

Dead or underperforming batteries are one of the leading causes of generator failure. Check battery voltage and charge regularly, and inspect for corrosion on terminals. Keep batteries clean, tight, and well-maintained.

Generator Maintenance Tip: Replace generator batteries every 2-3 years, even if they appear to be working, to avoid unexpected failures.

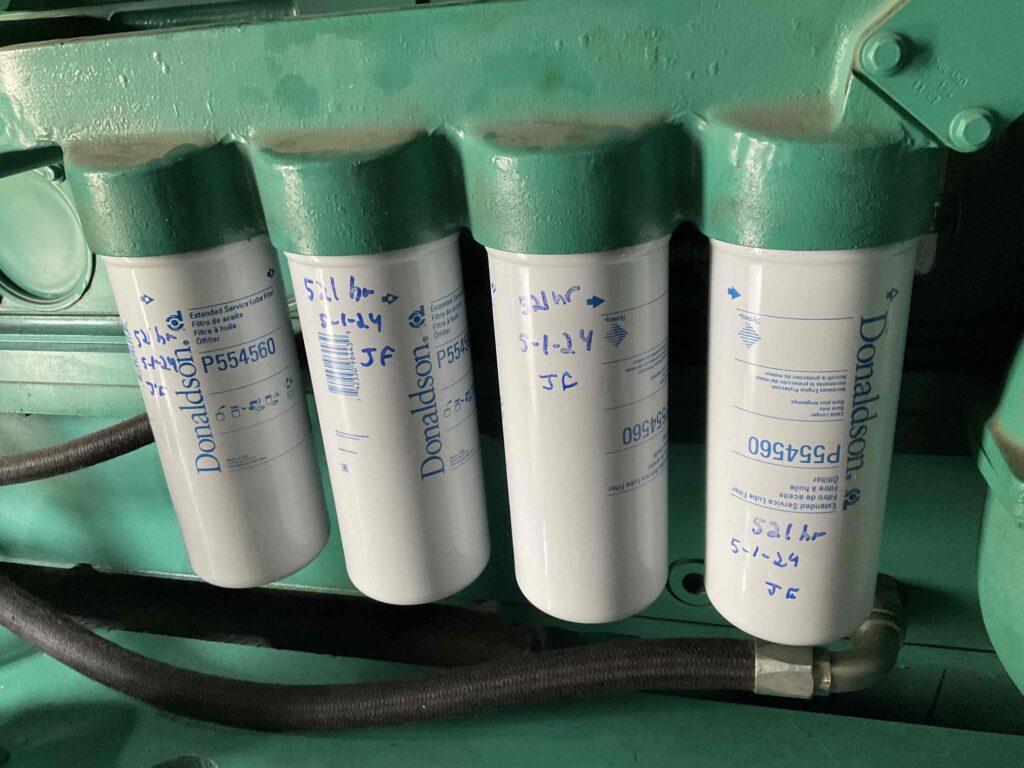

Change Oil and Filters on Schedule

Just like any engine, your generator’s oil degrades over time and use. Degraded and contaminated oil can cause engine wear and lead to costly repairs. Follow manufacturer guidelines for changing the oil, oil filter, fuel filter, and air filter at recommended intervals.

Generator Maintenance Tip: Use fluid sampling to monitor oil condition and catch early signs of contamination or engine wear.

Exercise Your Generator Regularly

Running your generator periodically, also called exercising, helps keep components lubricated, helps prevent fuel from degrading, and identifies operational issues before they become emergencies.

Generator Maintenance Tip: Schedule automatic weekly or bi-weekly exercise runs to make sure your generator is ready and to keep the batteries charged

Inspect and Clean the Cooling System

Generators can overheat quickly if the cooling system is compromised. Inspect coolant levels, radiator fins, and hoses for signs of blockage, leaks, or damage.

Generator Maintenance Tip: Flush and replace coolant per manufacturer recommendations and ensure airflow to the radiator is unobstructed.

Monitor and Maintain the Fuel System

Diesel fuel can degrade over time, leading to clogged filters and engine failure. Water contamination and microbial growth are also common in stored fuel.

Generator Maintenance Tip: Diesel fuel polishing can extend the life of your fuel supply. You should also conduct regular fuel sampling to monitor quality.

Don’t Ignore the Transfer Switch

The automatic transfer switch (ATS) is critical to switching from utility to generator power. If the ATS fails, the generator won’t power your building even if it’s functioning perfectly.

Generator Maintenance Tip: Schedule periodic ATS testing and inspection alongside your generator maintenance. Thermal Imaging can also be used to identify potential issues.

Keep Records and Follow a Maintenance Plan

Maintaining a log of all inspections, services, repairs, and test results helps ensure accountability and allows for trend analysis. A documented preventative maintenance plan keeps your generator compliant with local codes and manufacturer warranties.

Generator Maintenance Tip: Partner with a qualified generator service provider who can tailor a maintenance plan to your specific equipment and usage.

Final Thoughts

Your generator is only as reliable as your maintenance routine. Lack of regular preventative maintenance can lead to system failure and costly downtime. By staying proactive with inspections, fluid changes, battery tests, and exercising the system regularly, you ensure your standby power system is ready when you need it most.

Need Help Maintaining Your Generator?

At Weld Power Generator, we specialize in preventative maintenance programs designed to keep your generator running smoothly year-round. From diesel fuel polishing to transfer switch testing and everything in between, we provide turnkey solutions backed by decades of experience.

Contact us today to schedule a service or learn more about our maintenance programs.