Why Is My Generator Shutting Down? 7 Common Causes and Solutions

Why Is My Generator Shutting Down? In this article, we’ll explore the most common reasons why generators shut down and provide troubleshooting steps to help resolve these issues.

A standby or backup generator is a crucial asset for businesses to ensure uninterrupted power during outages. However, your generator shutting down can compromise reliability and leave you scrambling to restore power. Understanding why your generator is shutting down and how to address the issue is essential to keeping it operational when you need it most.

Table of Contents

Safety Disclaimer!

Generators contain high-voltage components, flammable fuel, and moving parts that can be hazardous. Attempting repairs without proper expertise may result in injury or equipment damage. Always follow safety guidelines and consult a professional. For expert service, contact Weld Power Generator.

Automatic Safety Shutdowns

Many generators have built-in safety shutdown mechanisms to protect against electrical faults, phase imbalances, or extreme conditions.

Causes:

- Short circuits or grounding faults

- Frequency or voltage fluctuations

- Internal mechanical failures

Solutions:

- Conduct an electrical inspection to identify faults

- Monitor voltage and frequency levels with a power analyzer

- Schedule professional maintenance for deeper diagnostics

Low Coolant Level or Overheating

One of the most frequent causes of a generator shutting down is overheating due to low coolant levels. If the coolant level drops below a critical point, the engine temperature rises, triggering an automatic shutdown to prevent damage.

Causes:

- Coolant leaks from hoses, radiators, or gaskets

- Blocked or dirty radiator reducing cooling efficiency

- Faulty water pump preventing coolant circulation

- Sensor malfunctions falsely detecting overheating

Solutions:

- Regularly inspect coolant levels and top off as needed

- Check for leaks and repair them promptly

- Clean the radiator and ensure proper airflow

- Test and replace faulty temperature sensors

Low Oil Pressure

Generators are equipped with oil pressure sensors that trigger a shutdown when pressure drops below a safe level to prevent engine damage.

Causes:

- Low oil level due to leaks or consumption over time

- Dirty or degraded oil causing poor lubrication

- Faulty oil pressure sensor

- Oil pump failure preventing circulation

Solutions:

- Check and maintain proper oil levels

- Change oil and filters according to the manufacturer’s schedule

- Inspect for leaks and repair them promptly

- Test the oil pump and replace if necessary

Fuel Supply Issues

Without adequate fuel supply, your generator cannot function properly. Generator shutting down due to fuel-related issues is common and can stem from multiple sources.

Causes:

- Empty or low fuel tank

- Clogged fuel filter restricting flow

- Air in the fuel system disrupting combustion

- Contaminated fuel (water, dirt, or microbial growth)

Solutions:

- Keep fuel tanks adequately filled and monitor fuel levels

- Replace clogged fuel filters as part of routine maintenance

- Bleed air from the fuel system if necessary

- Use fuel polishing services to remove contaminants

Battery or Charging Problems

Generators rely on batteries to start and maintain electrical functions. A weak or failing battery can result in a generator shutting down unexpectedly.

Causes:

- Weak or dead battery due to age or sulfation

- Loose or corroded battery terminals

- Faulty alternator or charging system

- Excessive battery drain due to electrical faults

Solutions:

- Perform regular battery voltage checks and replace aging batteries

- Clean and secure battery connections

- Test and repair the charging system

- Inspect for electrical faults that may drain battery power

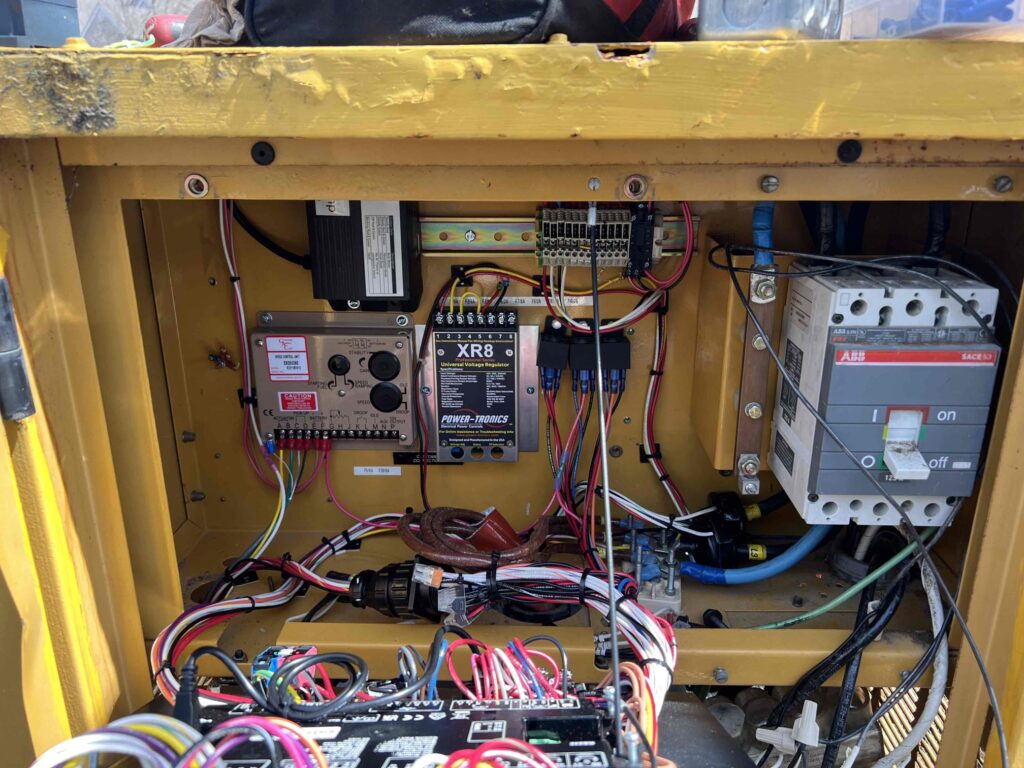

Faulty Sensors or Control Panel Issues

Generators have multiple sensors monitoring system performance. If a sensor malfunctions, it can lead to a generator shutting down unexpectedly.

Causes:

- Malfunctioning temperature, oil pressure, or voltage sensors

- Loose or damaged wiring connections

- Outdated or corrupted control panel software

Solutions:

- Run diagnostics to identify faulty sensors

- Secure or replace damaged wiring

- Update control panel software if applicable

Overloading

Generators are designed to handle a specific load capacity. Exceeding this limit can result in a generator shutting down automatically to prevent damage.

Causes:

- Running more equipment than the generator’s rated capacity

- Sudden power surges exceeding generator limits

- Faulty electrical connections causing load spikes

Solutions:

- Monitor load distribution and reduce non-essential loads

- Use a load management system to prevent spikes

- Ensure electrical connections are properly maintained

Preventative Maintenance: The Key to Reliability

Most instances of a generator shutting down can be prevented with regular maintenance. Implementing a preventative maintenance program that includes fluid sampling, battery inspections, fuel system cleaning, and load testing can help identify issues before they lead to failure.

At Weld Power Generator, we specialize in generator maintenance and repair services to ensure your power systems remain reliable. If your generator is experiencing shutdowns, contact us today for expert troubleshooting and servicing.

Final Thoughts – Generator Shutting Down

A generator shutdown can be inconvenient and costly, but understanding the common causes and how to address them can help keep your system running smoothly. By proactively maintaining your generator, you can ensure it delivers power when you need it most.

For more information or to schedule a service, reach out to Weld Power Generator, we’re here to keep your power on!

Really helpful👍🏻👍🏻