5 Things You Should Do to Prepare Your Generator for Cold Weather

As September rolls around and the colder New England air starts to settle in, it’s the perfect time to think ahead to winter. With unpredictable snowstorms, freezing temperatures, and power outages being all too common, generator maintenance is critical to ensure your business stays operational. Before the first snow, here are five essential tasks to prepare your generator for cold weather.

Table of Contents

Check and Change the Oil

Cold weather thickens engine oil, making it harder for your generator to start and run efficiently. To ensure smooth operation during winter, change the oil before the temperature drops. Make sure to use oil that’s appropriate for colder climates—check your manufacturer’s recommendations for the right viscosity. You can also perform fluid sampling to ensure the oil is in good condition and hasn’t broken down or become contaminated.

Why it helps: Regular oil changes and fluid sampling extend the life of your generator and reduce the chances of mechanical issues. Proper lubrication also helps prevent unnecessary wear and tear during startup in cold weather, ensuring smoother and quicker operation.

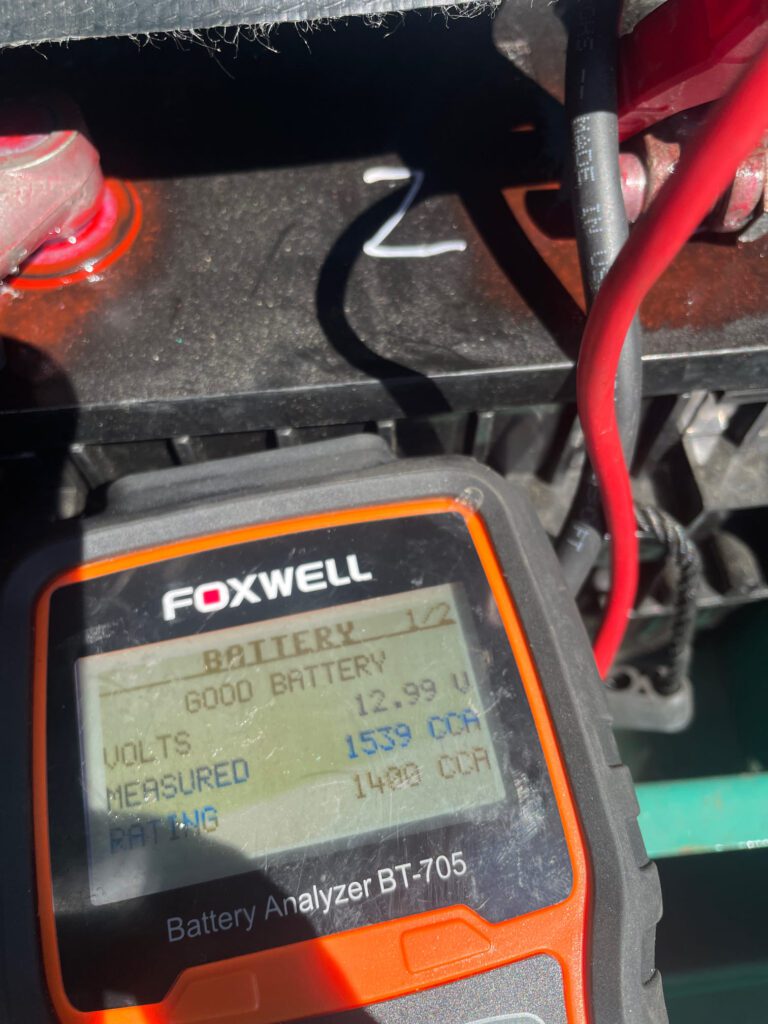

Test the Battery

Cold weather is notorious for draining battery power. A weak battery can struggle or fail to start your generator when you need it the most. Take the time to test the voltage and inspect the battery terminals for corrosion. If necessary, clean the terminals and replace a weak battery before it causes problems.

Why it helps: A healthy battery ensures reliable generator startup, which is especially important in an emergency. By addressing any battery issues in the fall, you avoid the frustration of needing a generator repair during a winter storm due to a dead battery.

Inspect and Replace Belts and Hoses

Extreme cold can make rubber belts and hoses brittle, leading to cracks and potential failure. Before winter sets in, inspect all belts and hoses for signs of wear, damage, or cracks. Replace any parts that look worn to prevent sudden breakdowns when your generator is needed most.

Why it helps: Preventative generator maintenance like this reduces the risk of your generator malfunctioning due to snapped belts or ruptured hoses, which can result in costly generator repair and downtime during a critical power outage.

Top Off or Replace Coolant

Your generator’s cooling system needs to be in top shape to handle cold-weather operation. Check the coolant levels and top them off if necessary. For areas where temperatures drop below freezing, ensure you’re using antifreeze rated for low temperatures to prevent the system from freezing up. Consider fluid sampling to ensure the coolant is still effective and not contaminated.

Why it helps: Maintaining the proper coolant levels helps prevent your generator from overheating and protects against freezing, both of which could cause permanent engine damage. It’s a simple step that keeps your equipment running smoothly during the harshest winter days.

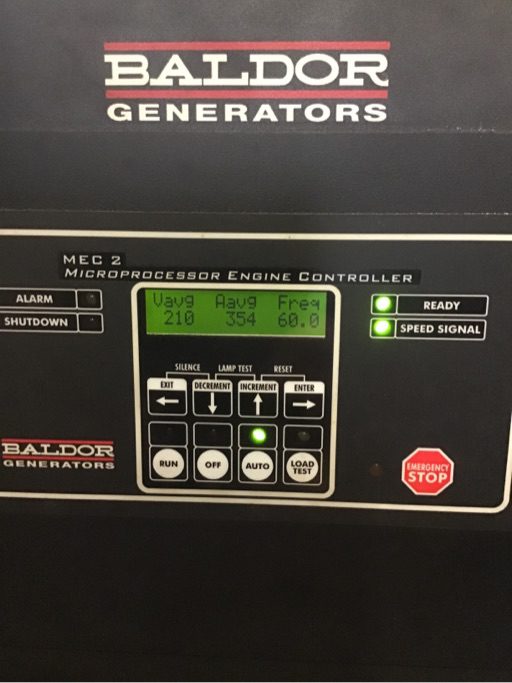

Perform a Load Test

As part of your cold-weather prep, perform a building load test to ensure your generator can handle the power demands it may face during an outage. A building load test simulates real operating conditions and helps identify any potential issues with your generator’s performance. It also gives you a chance to verify that your generator is producing the correct voltage and running efficiently.

Why it helps: A building load test ensures your generator is fully operational and capable of handling the load you expect it to power during a storm or outage. This proactive step provides peace of mind that your generator will perform when it matters most.

Final Thoughts On How To Prepare Your Generator for Cold Weather

As fall transitions to winter, ensuring your generator is ready for the cold is key to avoiding costly generator repair, extended downtimes, and the frustration of being without power. These simple generator maintenance steps—combined with fluid sampling and a building load test—can help your generator run more efficiently, last longer, and keep you powered through whatever New England’s winter throws your way.

Feel free to Contact Us is you have any questions or need assistance with preparing your generator for the winter months.