Oil, Coolant & Fuel Sampling

The Importance of Routine Fluid Sampling for Generator Maintenance

Ensuring your generator is in top working condition requires more than just periodic inspections; it demands routine fluid sampling to catch early signs of potential issues. Weld Power Generator provides comprehensive fluid sampling services to help you maintain your generator’s efficiency and longevity. Here’s why each type of fluid sampling is critical for establishing baselines and detecting internal problems before they lead to costly failures.

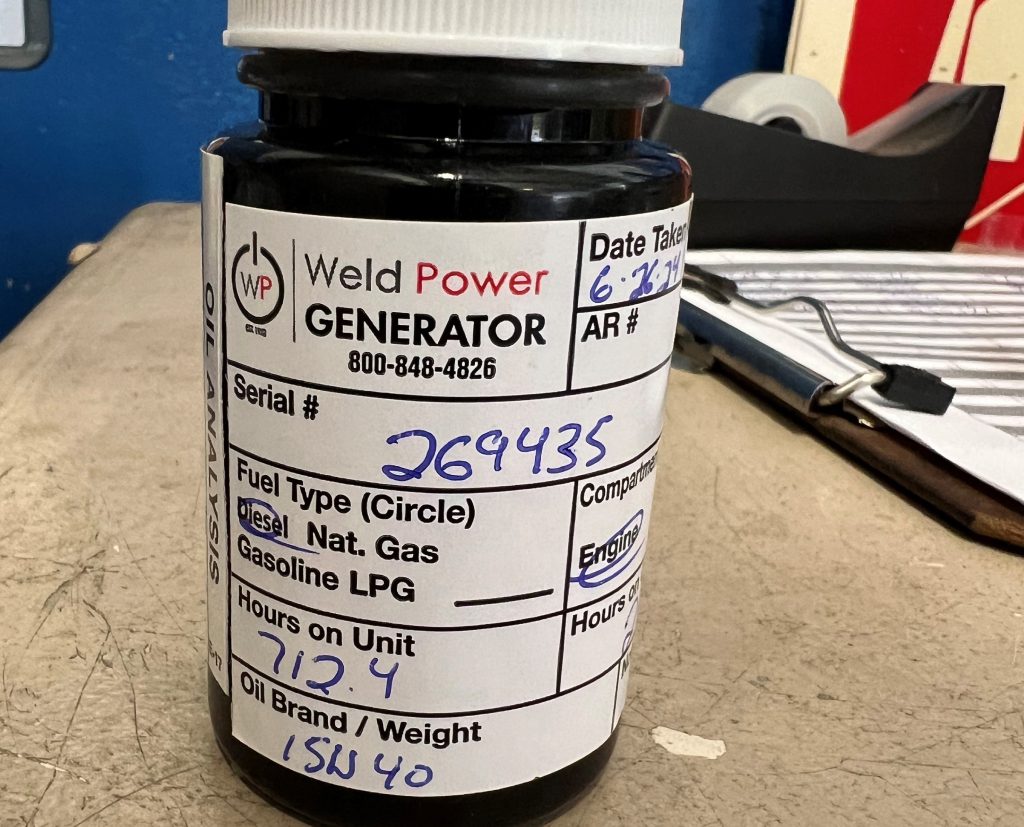

Oil Sampling: The Key to Engine Health

Regular oil sampling is an indispensable part of generator maintenance. By performing oil analysis, you can detect early signs of wear, contamination, and other issues that might lead to engine trouble. This proactive approach allows you to monitor the condition of your generator’s engine, ensuring it operates smoothly and efficiently. Routine oil sampling helps establish a baseline for your equipment’s performance, making it easier to identify deviations that could signal developing problems.

Incorporating regular oil sampling into your maintenance plan not only prevents unexpected breakdowns but also extends the life of your generator. Trust Weld Power Generator for expert oil sampling services to keep your generator in peak condition.

View some of our customer stories

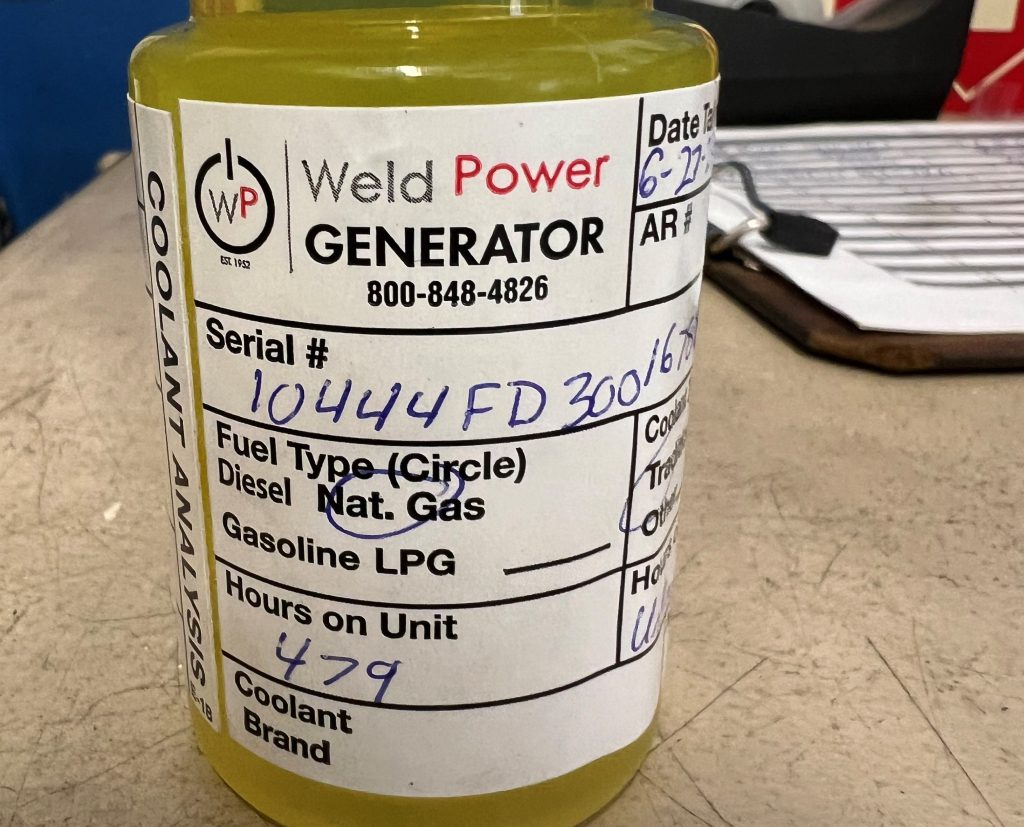

Coolant Sampling: Preventing Overheating and Corrosion

Coolant sampling is crucial for maintaining the optimal performance of your generator. Regular analysis of coolant fluid can reveal issues such as contamination, corrosion, and degradation, which can lead to overheating and potential engine failure. By detecting these problems early, you can address them before they escalate, ensuring your generator runs efficiently and reliably. Establishing a routine for coolant sampling allows you to track the health of your cooling system over time, making it easier to pinpoint and rectify any anomalies. This preventive measure not only extends the lifespan of your generator but also avoids costly generator repairs and downtime. Keep your generator running smoothly with Weld Power Generator’s professional coolant sampling services.

Building Load Testing is the only proactive way to verify that the system will work as designed.

Fuel Sampling: Ensuring Clean and Efficient Operations

Fuel sampling is essential for maintaining the reliability and efficiency of your generator. Regular analysis of fuel quality can detect contaminants, water, and microbial growth that could impair performance and cause significant damage. By performing routine fuel sampling, you can identify and mitigate potential issues before they result in engine malfunctions or failures. This practice helps maintain the quality of your fuel supply, ensuring your generator remains operational when you need it most.

Establishing a baseline through consistent fuel sampling enables you to spot deviations quickly, preventing unexpected breakdowns and extending the life of your equipment. Prioritize your generator’s health with expert fuel analysis services from Weld Power Generator.