The 6 Game-Changing Benefits of Thermal Imaging for ATS: Avoid Failures

Thermal imaging, also known as infrared scanning, provides a non-invasive, proactive way to assess the health of an ATS. In critical power systems, Automatic Transfer Switches (ATS) play a pivotal role by seamlessly switching a facility’s load from utility power to backup generator power during an outage. Given their importance, ensuring the ATS operates reliably is non-negotiable. One of the most effective tools for identifying hidden issues before they lead to costly failures is thermal imaging. Here’s why incorporating thermal imaging into your ATS maintenance routine is a smart move.

Table of Contents

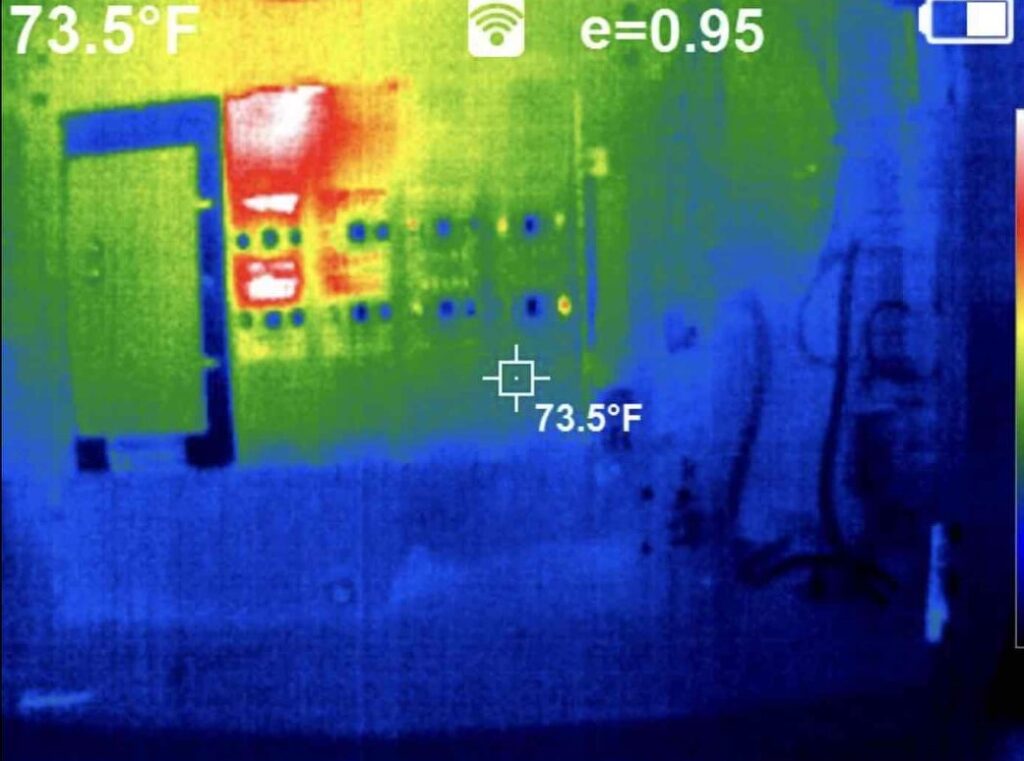

Early Detection of Overheating Components

Automatic transfer switches consist of electrical connections, contacts, relays, and internal wiring, all of which can degrade over time. A failing connection or overloaded circuit might not be visible during routine visual inspections, but thermal imaging detects abnormal heat patterns, pinpointing hotspots caused by:

- Loose or corroded connections

- Imbalanced loads

- Overloaded components

- Contact wear or pitting

Identifying these anomalies early can prevent outages and unplanned downtime.

Non-Disruptive and Safe Inspection

One of the biggest advantages of thermal imaging is that it can be performed without interrupting operations. Technicians can conduct thermal scans while the ATS is under load, capturing a real-time picture of how the system performs under stress. It’s also safer for personnel, as inspections are performed at a distance without opening energized panels unnecessarily.

Supports Preventive and Predictive Maintenance

Routine thermal scans can be integrated into your preventive maintenance plan to create a baseline profile of your ATS’s normal operating temperature. Over time, deviations from this baseline serve as indicators of developing problems, empowering you to act before failure occurs.

This predictive approach reduces emergency service calls, extends the life of your equipment, and ensures better compliance with life-safety and regulatory standards in healthcare, data centers, and other critical environments.

Reduces the Risk of Fire or Equipment Damage

Overheated electrical components are a leading cause of electrical fires in commercial and industrial buildings. By identifying heat anomalies well in advance, thermal imaging helps mitigate the risk of fire, component failure, and collateral damage to adjacent systems.

Provides Visual Documentation for Reporting and Audits

Thermal imaging produces easy-to-understand visual reports that clearly show potential issues. These images and data points can be included in maintenance records, presented during audits, or used to justify repairs and upgrades to stakeholders.

For facilities with compliance obligations, such as hospitals or financial institutions, this level of documentation enhances accountability and helps meet industry standards.

Cost-Effective Risk Mitigation

Thermal imaging is a cost-effective investment compared to the consequences of a failed ATS, such as downtime, emergency repairs, or equipment replacement. By catching problems early, facility managers can plan maintenance during scheduled downtimes and avoid premium service rates for emergency repairs.

Conclusion: A Smarter Way to Maintain Your ATS

As the heart of your backup power system, the automatic transfer switch must be in peak condition when you need it most. Thermal imaging offers a smart, proactive, and non-intrusive method to ensure your ATS stays reliable. When combined with routine inspections and maintenance, thermal imaging helps protect your facility from unexpected failures and costly downtime.

Contact us today to have thermal imaging added to your ATS maintenance plan.