Why Your Generator Needs a Block Heater – 7 Critical Reasons

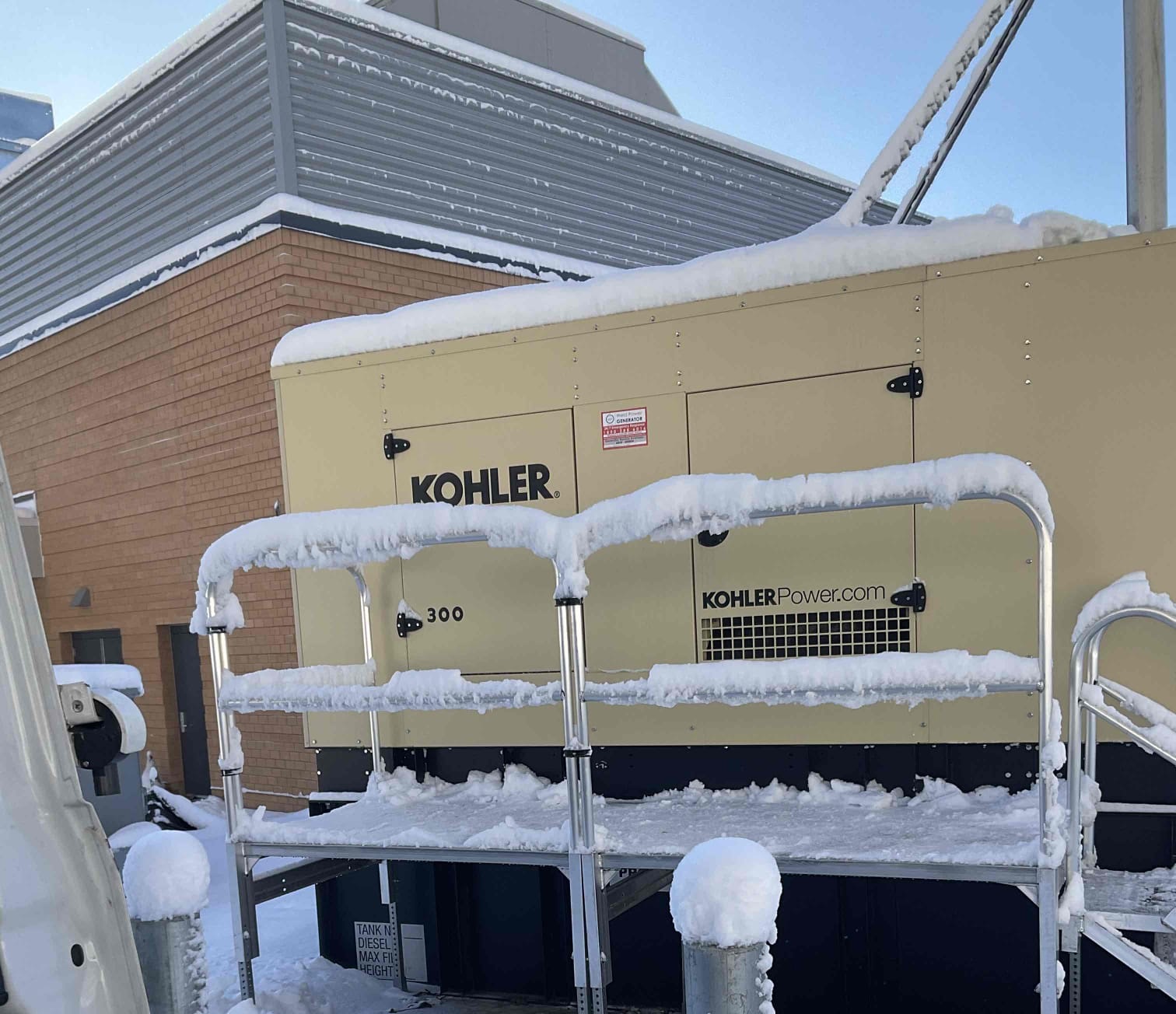

When it comes to ensuring reliable power from a standby generator, especially in cold climates, one often-overlooked component is the block heater. A generator block heater keeps the engine warm when not in use, allowing it to start smoothly and reach optimal operating conditions quickly. In this article, we’ll explore why block heaters are essential for your generator, how they work, and best practices for maintenance.

Table of Contents

Why Are Block Heaters Important?

Cold temperatures can cause issues for generator engines, particularly diesel engines, which rely on high compression to ignite the fuel-air mixture. When an engine is cold, the oil is thicker, and metal parts are more rigid, making it harder to start. A block heater solves this by keeping the engine block and coolant warm, allowing the engine to reach its required temperature more quickly. This brings several benefits:

- Faster Start-Up: Block heaters allow for quick, reliable starts in cold weather, preventing costly delays and ensuring power is available when needed.

- Reduced Wear on Engine Components: Cold starts increase wear on engine parts due to metal contraction and thickened oil. A block heater keeps these components at an optimal temperature, reducing wear and extending the generator’s lifespan.

- Improved Fuel Efficiency: Cold engines tend to burn more fuel. By pre-warming the engine, a block heater reduces the amount of fuel needed during start-up.

- Compliance and Safety: Many industries require backup power systems to meet strict reliability standards. For critical applications, such as hospitals, data centers, or food storage facilities, having a block heater improves the generator’s dependability.

How Does a Block Heater Work?

A block heater is essentially an electric heating element that sits in or around the engine block or coolant system. The heater warms the coolant, which circulates through the engine block and helps maintain a consistent temperature. Here’s how it works:

- Coolant Heating: The heater warms the coolant, which maintains the temperature in the engine block even when the generator is off. This helps keep the engine ready for quick starting.

- Thermostatic Control: Many block heaters have a thermostat to regulate the temperature, preventing overheating and ensuring the system stays within an optimal range. This minimizes energy consumption and prolongs the life of the heater.

- Automatic Operation: Block heaters can be set up to run continuously or operate automatically during cold conditions, depending on the needs of the facility. This automation ensures the generator is always ready for immediate use.

Maintenance Tips for Block Heaters

To maximize the reliability and longevity of your generator block heater, regular maintenance is essential. Here are some best practices to keep it in top shape:

- Inspect for Wear and Tear: Periodically check the heater and its components for signs of wear, corrosion, or leaks. Coolant leaks or a burned-out heating element can reduce the block heater’s effectiveness.

- Test Thermostats: Ensure that thermostats are functioning correctly. If they aren’t maintaining the correct temperature, the block heater could fail to prevent cold starts or waste unnecessary energy.

- Check Electrical Connections: Over time, electrical connections can loosen or corrode, leading to poor heater performance. Regularly inspect these connections to avoid issues.

- Monitor Coolant Levels: Since block heaters rely on coolant circulation, it’s important to keep coolant levels within the recommended range. Low coolant can cause the engine to overheat, damaging the heater and engine components.

- Schedule Routine Inspections: Regular generator maintenance should include a block heater inspection to ensure all components are functioning optimally. Scheduling seasonal maintenance can also prepare the generator for changes in weather.

When Should You Replace a Block Heater?

Block heaters typically last several years, but they do wear out over time. Signs that it may be time for a replacement include:

- Inconsistent Heating: If the engine doesn’t reach optimal temperature as quickly as before, the heater could be losing effectiveness.

- Visible Corrosion or Damage: Corroded or damaged components can compromise the heater’s function and may indicate a replacement is necessary.

- Faulty Thermostat: If the thermostat fails, it may be cost-effective to replace the entire block heater rather than repair it.

Conclusion

For generator reliability in cold weather, a block heater is a must-have accessory. It improves starting performance, minimizes wear on the engine, and ensures fuel efficiency, helping to keep your generator ready for any emergency. With regular inspection and maintenance, a block heater can significantly extend the life of your generator and ensure seamless operation when it’s needed most.

For those looking to enhance their generator’s performance in cold weather, consider scheduling an assessment with Weld Power Generator. Our team can help you determine the best block heater options, install them correctly, and keep your entire generator system well-maintained year-round.