NJ Air Quality Standards: 3 Strategies to Keep Generator Compliant

IMPORTANT NOTE: EMERGENCY GENERATORS CAN BE USED WHENEVER NEEDED FOR TRUE EMERGENCIES, REGARDLESS OF THE AIR QUALITY. The article below only applies only to normal testing and maintenance usage. Please visit NJDEP for complete details.

As businesses and facilities across New Jersey depend on backup generators for critical operations, routine testing of these systems is essential to ensure their reliability. However, NJ Air Quality Standards have strict regulations on when generators can be operated for testing and maintenance. New Jersey’s stringent environmental regulations require facility managers to understand both the environmental impact and the legal responsibilities tied to generator testing.

Table of Contents

Permitting and Compliance with NJ Air Quality Standards

To legally operate and test generators, businesses must comply with NJDEP regulations regarding air permits. These permits outline the specific conditions under which generators can be tested, including:

- Hours of operation: Limits are placed on how long generators can be tested annually, which helps control emissions over time.

- Emissions monitoring: Facilities may be required to monitor and report emissions to ensure they remain below threshold levels.

- Recordkeeping: Detailed records of all testing activities, including runtime, fuel use, and maintenance, must be kept and submitted to the NJDEP when required. A remote monitoring system can track these records for you.

Facilities testing generators in non-attainment areas—regions that do not meet federal air quality standards—may face even stricter rules. The state has classified parts of New Jersey as non-attainment for ozone and fine particulate matter (PM2.5), necessitating careful planning of generator testing to stay within legal limits.

Procedure: Checking the Air Quality Forecast

New Jersey’s air quality can vary significantly day to day, and it’s essential to ensure that your generator testing or maintenance activities don’t occur on days when air pollution is forecasted to be high. This procedure will guide you through checking the air quality forecast to determine if you can proceed with generator testing or if it needs to be rescheduled.

- Check the air quality forecast the day before your scheduled generator testing or maintenance. It is important to check after 4:00 PM to get the most accurate and up-to-date forecast for the following day.

- Go to the New Jersey Department of Environmental Protection (NJDEP) air quality website or AirNow.gov.

- Look for the forecast for tomorrow’s date in the “Forecast” section. This forecast will indicate air quality levels across different regions of New Jersey.

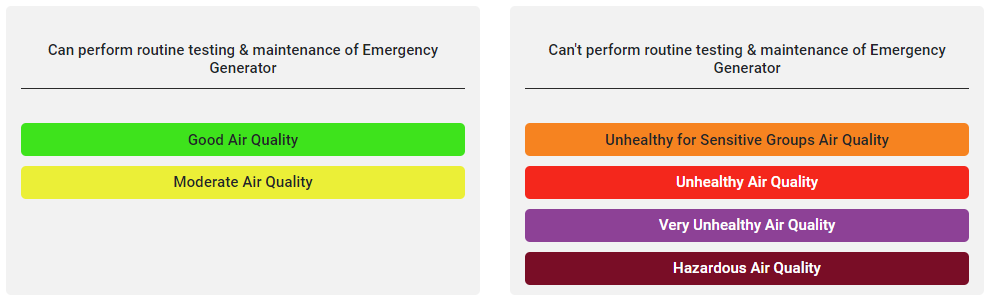

- Review air quality conditions, to see if testing and maintenance can be performed

Then you cannot perform generator testing or maintenance the following day. This restriction helps minimize your facility’s contribution to poor air quality on high-pollution days.

- If air quality is forecasted to be poor, you will need to reschedule your testing for another day. Be sure to choose a date when air quality levels are expected to be better.

- After rescheduling, don’t forget to re-check the air quality forecast after 4:00 PM on the day before the newly scheduled testing. Repeat the procedure to ensure compliance with air quality regulations.

By following this procedure, you can ensure that your facility remains compliant with New Jersey’s air quality guidelines, while also doing your part to reduce emissions on days when air pollution is expected to be particularly high.

Reducing Emissions During Testing

Although generator testing is a necessary practice, there are steps that businesses can take to reduce their environmental impact while remaining compliant with NJDEP regulations.

- Test Frequency and Duration: Consider reducing the frequency and duration of non-emergency testing, while still adhering to manufacturer recommendations for optimal generator performance. Limiting run times can significantly decrease emissions.

- Use Cleaner Fuels: Where possible, transition to cleaner fuels such as natural gas or ultra-low sulfur diesel (ULSD), which produce fewer emissions compared to traditional diesel.

- Install Emissions Control Devices: Technologies such as diesel particulate filters (DPFs) or selective catalytic reduction (SCR) systems can help reduce particulate matter and NOx emissions during generator testing.

- Remote Monitoring: Incorporate remote monitoring technology to evaluate generator performance without having to conduct full-scale load tests as frequently. Remote monitoring can help detect performance issues early, reducing the need for more frequent or lengthy tests. A remote monitoring system will also assist with the state required record keeping.

Best Practices for Generator Testing in New Jersey

When conducting generator testing in New Jersey, it is critical to balance operational readiness with environmental responsibility. Here are some best practices to keep in mind:

- Schedule testing during off-peak hours: Perform tests at times when air quality is typically better, such as early morning or late evening. This helps to mitigate the cumulative impact of emissions during high traffic or industrial periods.

- Stay informed about local air quality alerts: New Jersey often issues air quality alerts when pollution levels are high, especially during the summer. Avoid testing generators during these periods to minimize your contribution to poor air quality.

- Work with experienced service providers: Choose a generator maintenance provider familiar with New Jersey’s air quality regulations. This ensures that your facility remains compliant while maximizing the efficiency of your testing procedures.

- Use Remote Monitoring to control Generator Exercise: Exercising your generator is a simple way to make sure your generator will be ready when you need it. However you will not be able to set-up automated exercise schedules and remain in compliance. If you have a remote monitor, your generator can be exercised through an app on days when the air quality permits it.

Conclusion

In New Jersey, maintaining backup generator readiness through testing is critical for facility operations, but so is compliance with air quality regulations. By following NJDEP guidelines, incorporating emission-reducing practices, and staying informed about local air quality, businesses can ensure that their generator testing procedures are both effective and environmentally responsible. This balance is key to safeguarding not only your facility’s power systems but also New Jersey’s air quality.

For more information please see the notices below from the New Jersey Department of Environmental Protection