12 Common Generator Repairs on a Commercial Generator: Beyond Routine Maintenance

Commercial generators are vital for providing consistent power in various industrial and commercial settings. Regular maintenance is essential, but beyond routine upkeep like oil changes, filter replacements, and battery checks, certain critical parts often need replacement to ensure the generator’s reliability and efficiency. This article focuses on the most common generator repairs in commercial generators.

Table of Contents

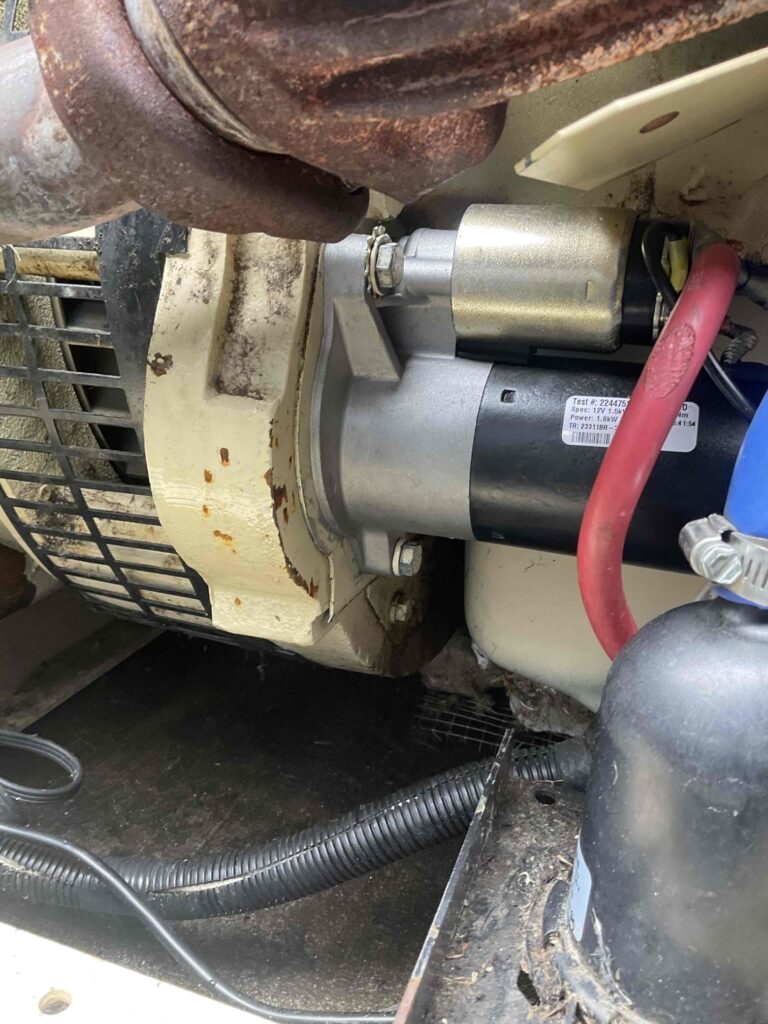

Starter Motor

Function: The starter motor is responsible for cranking the engine to initiate operation.

Why Replacement is Needed: Over time, the starter motor can wear out due to frequent use, causing it to fail or become less effective at starting the generator.

Signs of Wear: Difficulty starting the generator, unusual noises during startup, or a complete failure to start.

Control Panel & Electrical Components

Function: The control panel houses various electrical components and circuits that manage the generator’s operation, including monitoring, regulation, and safety features. This could include Microcontroller, processors, , AVR (automatic voltage regulator), relays, sensors, circuit breakers, timers, communication modules, alarm systems, controls, inverters, data loggers, fuses, transducers, indicator lights or display, and more.

Why Replacement is Needed: Electrical components can fail due to wear, rodent damage, electrical surges, or environmental factors like moisture and temperature fluctuations.

Signs of Wear: Malfunctioning displays, error messages, alarms, unresponsive controls, or erratic generator behavior.

Fuel Injectors (for Diesel Generators)

Function: Fuel injectors deliver fuel into the engine’s combustion chambers in precise amounts for efficient combustion.

Why Replacement is Needed: Over time, fuel injectors can become clogged or worn, reducing their efficiency and affecting engine performance.

Signs of Wear: Reduced engine performance, increased fuel consumption, or black smoke from the exhaust.

Fuel Pumps

Function: Fuel pumps supply fuel from the tank to the engine, ensuring the generator has a steady fuel flow for continuous operation.

Why Replacement is Needed: A failing fuel pump can cause fuel delivery issues, leading to reduced engine performance or generator downtime.

Signs of Wear: Signs of a failing fuel pump include engine sputtering, difficulty starting, decreased fuel efficiency, and unusual noises from the fuel tank area.

Wiring

Function: Wiring harnesses connect various electrical components within the generator, allowing for the transmission of electrical signals and power.

Why Replacement is Needed: Damaged or corroded wiring can cause operational issues, including short circuits, intermittent power supply, or complete electrical failure, necessitating replacement.

Signs of Wear: Signs of worn wiring harnesses include visible fraying or cracking, visible rodent damage, electrical malfunctions, frequent tripping of circuit breakers, and burning smells or smoke.

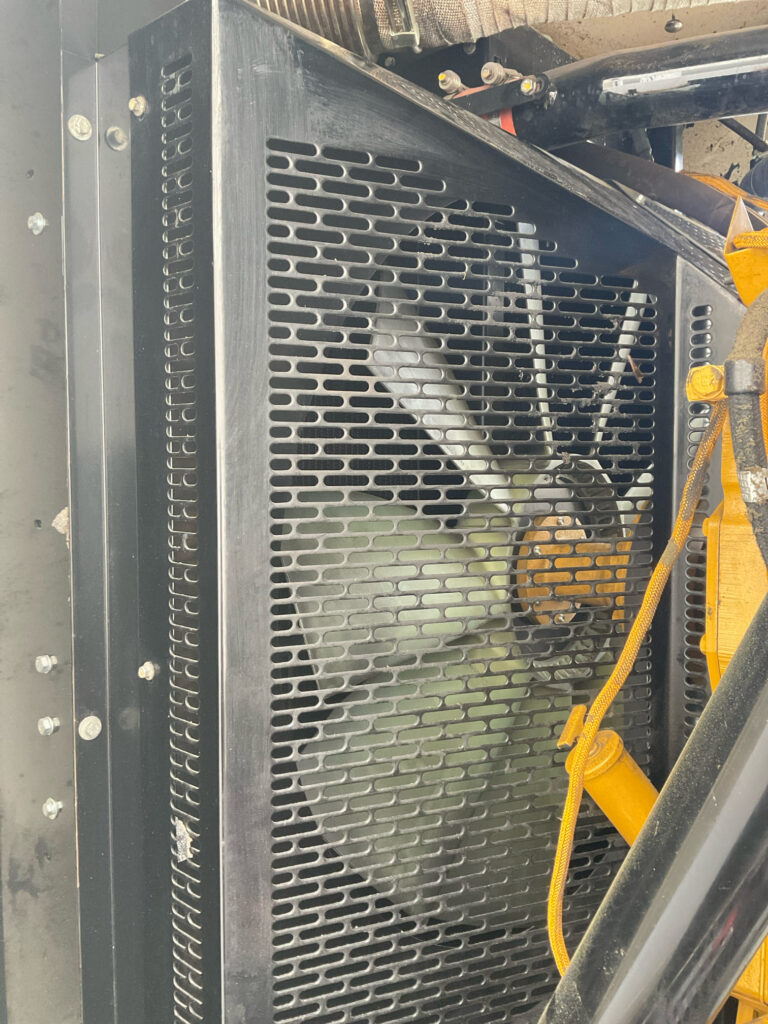

Radiator and Cooling System Components

Function: The radiator and cooling system components dissipate heat from the engine to prevent overheating.

Why Replacement is Needed: Radiators and cooling system parts can become clogged with debris, corroded, or damaged, reducing their effectiveness.

Signs of Wear: Overheating engine, coolant leaks, or reduced coolant levels.

Exhaust System Components

Function: The exhaust system directs harmful gases away from the generator and reduces noise.

Why Replacement is Needed: Components like the muffler and exhaust pipes can corrode, crack, or become damaged over time.

Signs of Wear: Excessive noise, visible exhaust leaks, or the smell of exhaust fumes.

Bearings and Bushings

Function: Bearings and bushings support rotating components and reduce friction between moving parts.

Why Replacement is Needed: Bearings and bushings can wear out over time due to constant motion and load, leading to increased friction and potential damage to other parts.

Signs of Wear: Unusual noises, increased vibration, or reduced efficiency.

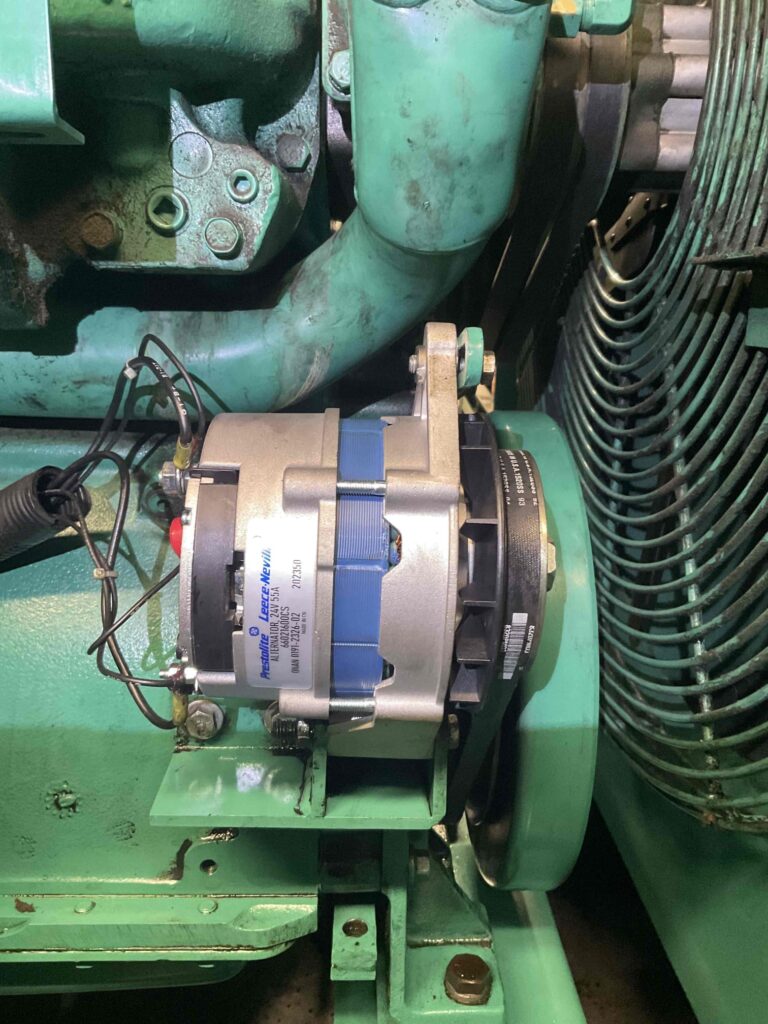

Alternator Windings

Function: The windings in the alternator generate electrical power through electromagnetic induction.

Why Replacement is Needed: Windings can degrade over time due to heat, vibration, and electrical stress, leading to reduced efficiency or failure.

Signs of Wear: Reduced power output, overheating, or visible damage to the windings.

Rotor and Stator Components

Function: The rotor and stator are key parts of the generator that work together to produce electrical power.

Why Replacement is Needed: These components can wear out or become damaged due to mechanical stress, heat, or electrical faults.

Signs of Wear: Reduced efficiency, unusual noises, or visible damage.

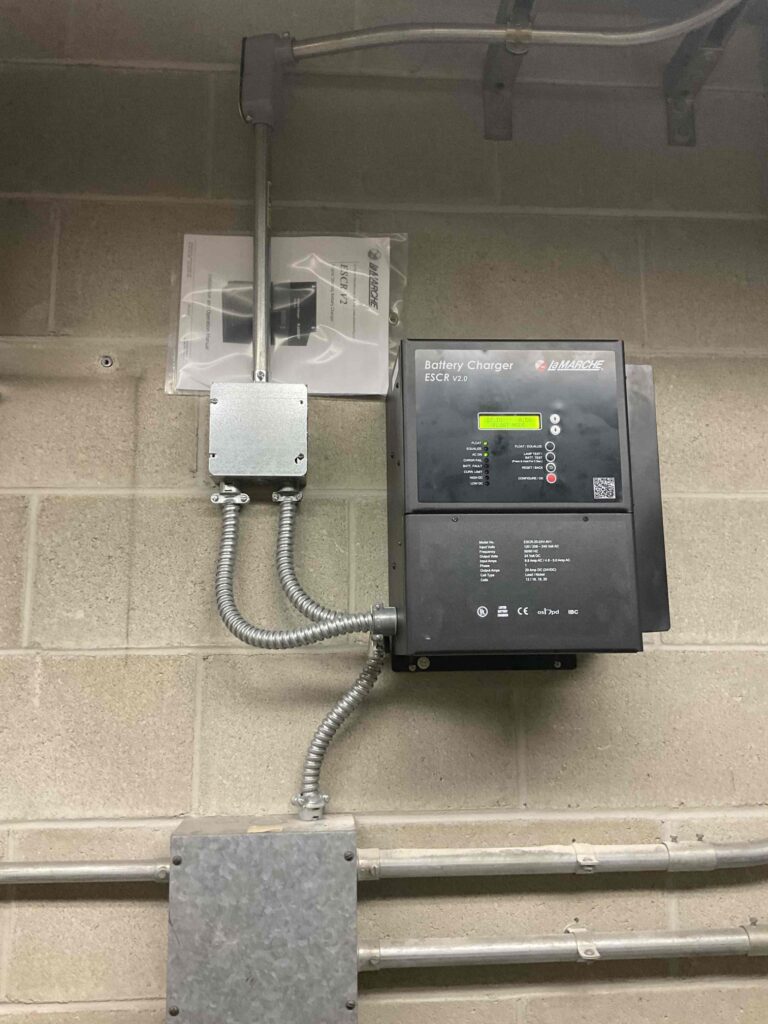

Battery Chargers

Function: Battery chargers keep the generator’s starting battery charged and ready for use by supplying it with a stable electrical current.

Why Replacement is Needed: A failing battery charger can lead to an undercharged or overcharged battery, compromising the generator’s ability to start when needed.

Signs of Wear: Signs of a failing battery charger include a battery that frequently loses charge, difficulty starting the generator, and visible damage or corrosion on the charger unit.

Block Heaters

Function: Block heaters keep the engine at an optimal temperature to ensuring it starts easily and operates efficiently in cold weather.

Why Replacement is Needed: A failing block heater can lead to difficulties starting the engine, increased wear on engine components, and reduced overall efficiency, especially in cold climates.

Signs of Wear: Signs of a failing block heater include slow or difficult engine starts in cold weather, a noticeable drop in engine performance, and visible damage or leakage from the heater unit.

Common Generator Repairs Conclusion

While routine maintenance is crucial for the longevity and performance of commercial generators, it’s equally important to be aware of other generator repairs that may be need over time. Regular inspections and prompt replacement of these parts and components can prevent unexpected failures and ensure that your generator continues to provide reliable power when needed. By staying proactive with generator maintenance and part replacement, you can maximize the efficiency and lifespan of your equipment, ensuring uninterrupted power supply for your operations.

Contact us for any generator repairs needs.