6 Dangerous Generator Hazards and How to Avoid Them

Generator hazards are a serious concern for any business relying on backup power. While commercial generators are essential for maintaining operations during outages, they can pose significant safety, environmental, and operational risks if not properly installed, maintained, or operated. Whether permanently installed or mobile, these powerful machines require careful oversight. In this article, we’ll outline the most common hazards associated with commercial generators and how businesses can mitigate them.

Table of Contents

Carbon Monoxide Poisoning

One of the most largest generator hazards, which is often overlooked is carbon monoxide (CO) exposure. Commercial generators are typically powered by diesel, natural gas, or propane. The engines emit CO, a colorless, odorless gas that can be lethal in high concentrations.

Mitigation Tips:

- Install CO detectors near generator rooms and occupied areas.

- Ensure proper ventilation in enclosed generator spaces.

- Ensure that the exhaust system is functioning properly.

- Make sure there are no open windows or air intakes near the generator exhaust.

Electrical Hazards and Backfeeding

Improper connections or faulty wiring can lead to electrocution or backfeeding. Backfeeding is a dangerous condition where power flows in reverse through utility lines, putting utility workers and equipment at risk.

Mitigation Tips:

- Use transfer switches to isolate the generator from the grid.

- Only qualified technicians should install or modify generator systems.

- Conduct regular safety inspections.

Fuel-Related Risks

Generator fuel is combustible, making proper storage and handling essential to site safety. Improper practices can lead to dangerous spills, fires, or even explosions, especially in high-traffic or enclosed areas. Leaking fuel can also contaminate soil and groundwater, creating costly environmental liabilities. As one of the most common generator hazards, fuel-related incidents highlight the need for strict compliance with safety regulations and routine inspections.

Mitigation Tips:

- Store fuel in approved, clearly labeled containers away from ignition sources.

- Conduct regular inspections of fuel tanks, lines, and containment systems.

- Train staff on proper fueling and spill response procedures.

Overheating and Fire Hazards

Generators produce significant heat during operation. Inadequate airflow, improper load balancing, or neglected maintenance can cause overheating, potentially leading to fires.

Mitigation Tips:

- Keep the generator area clear of debris, weeds, and combustibles.

- Maintain radiator, coolant, and exhaust systems to ensure efficient heat dissipation.

- Perform building load testing or load bank testing while monitoring temperatures.

- Use thermal imaging to identify anomalies.

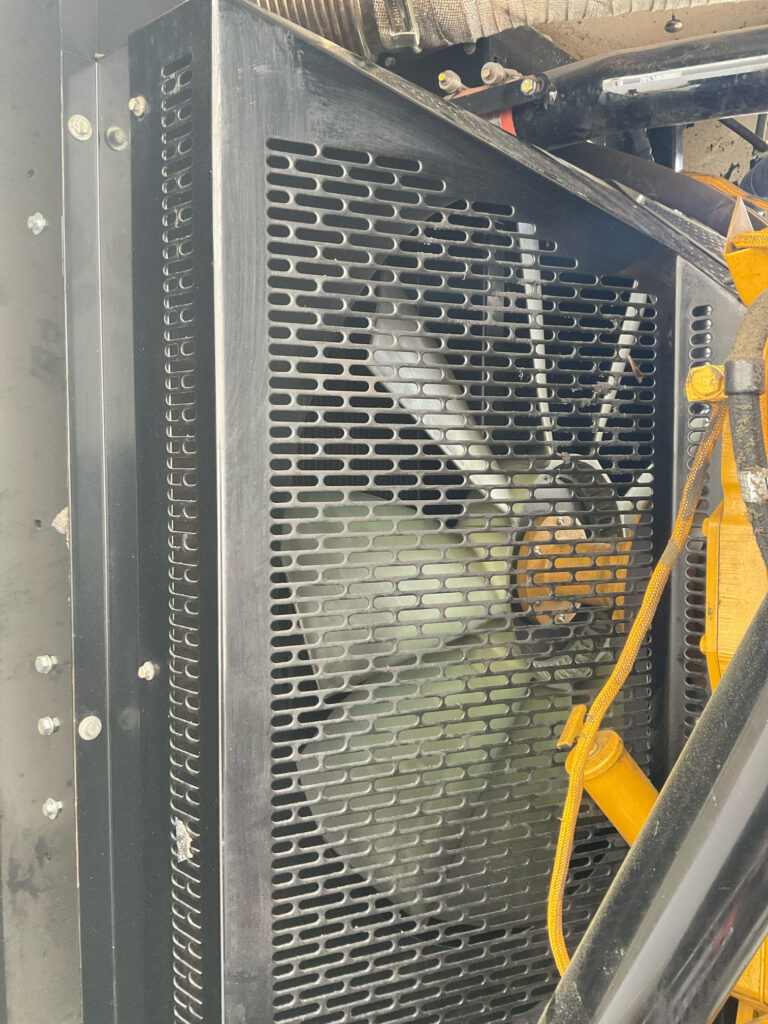

Mechanical Failures and Moving Parts

Moving parts like belts, fans, and alternators can cause serious injury if safety guards are missing or if untrained personnel attempt repairs while the unit is running. These mechanical risks are among the most overlooked generator hazards, especially in facilities where multiple teams may access the equipment. Without proper lockout/tagout procedures and training, the risk of entanglement or impact increases significantly. Addressing these generator hazards requires strict safety protocols and routine equipment checks.

Mitigation Tips:

- Always follow lockout/tagout procedures during maintenance.

- Keep protective guards in place and secured.

- Provide technician training and enforce PPE usage.

Environmental Hazards

Leaking oil, fuel, or coolant can contaminate soil and water sources, leading to environmental penalties and costly cleanup efforts.

Mitigation Tips:

- Use double-walled tanks and spill containment systems.

- Perform routine leak inspections.

- Maintain proper record-keeping to demonstrate compliance with EPA regulations.

Noise Exposure

Generators can be extremely loud, especially in enclosed or urban environments. Prolonged exposure to high noise levels can cause hearing loss and stress for workers or nearby residents.

Mitigation Tips:

- Install acoustic enclosures or sound-attenuating barriers.

- Issue hearing protection to personnel working near generators.

- Comply with local noise ordinances and workplace safety standards.

Conclusion: Generator Hazards

While commercial generators are invaluable for keeping your operations running during outages, they are not without risks. Recognizing and addressing the hazards associated with their use is essential for protecting your people, property, and the environment. Partnering with a trusted service provider like Weld Power Generator ensures your equipment is installed correctly, regularly maintained, and operates safely when you need it most.

Need Help Managing Generator Safety?

Contact Weld Power Generator for professional inspections, preventative maintenance, and 24/7 emergency service to reduce risk and maximize uptime.